After having complete the mill (see How I made a mill from foamboard) and giving it a test run ......

..... I felt that, in real life, the mill stream would have had some sort of sluice gate to control the flow of water on to the wheel.

After sketching a very basic design, I decided to use some offcuts of foamboard for its construction. I did consider using wood (too prone to rotting) and plasticard (too flimsy) but decided the 5mm thickness of the foamboard would give the gate a fairly substantial, chunky appearance.

The first task was to make the lower guides for the sliding gate. Four pieces of 5mm x 60mm and two 18mm x 60mm lengths of foamboard were cut out.

Two of the narrow pieces were glued on to each of the wider pieces, 5.5mm apart to act as guides for the sluice gate

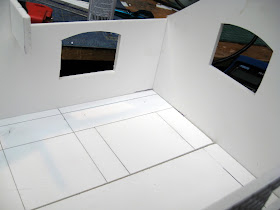

A 30mm x 150mm piece of foamboard was cut out to act as the platform. A 45mm x 5.5 mm slot was cut into the centre of the platform to allow the sluice gate to rise through it.

The sluice guides were glued .....

...... either side of the slot in the platform.

A 85mm x 40mm piece of foamboard was cut out for the sluice gate.

The gate was then slotted into the guides to check it was the right size. A small amount was shaved off the edges to ensure it slid smoothly.

The upper guides for the gate were mades from four 65mm x 5mm and two 70mm x 25mm pieces of foamboard.

These were then glued above the platform and a 25mm x 52mm piece of foamboard glued across the top.

The semi completed sluice gate was then test-fitted into its location to make sure it fitted and also to determine the size and shape of the blanking pieces which were required either side of the gate.

These were cut from offcuts of foamboard and glued either side of the sluice gate guides.

A couple of sets of plastic spur gears and racks were ordered from Technobots.

The rack was detached from the sprue .......

..... and the moulding reduced in depth with a craft knife.

A slot was cut into the platform to accommodate the rack......

...... and the rack was glued to the centre of the sluice gate.

Once the glued had dried, the sluice gate was fitted back into the guides.

A figure of eight link was drilled and filed from a piece of 1mm thick brass shim, 13mm x 5mm with 2mm diameter holes near each end.

2mm diameter brass rod was soldered into the holes.

..... and the excess solder filed smooth.

A couple of 3mm diameter holes were drilled in the upper sluice guide and the crank handle assembly was inserted. A small spur gear was positioned midway along the longer shaft on the crank to engage with the rack.

A small spur gear was positioned behind the crank handle and a pawl fashioned from an offcut of 1mm thick plasticard.

A 5mm diameter brass washer was then soldered on to the other end of the shaft to retain it.

Two 75mm long posts were cut from 4mm diameter brass rod. The lower 20mm of each post was bent through 90 degrees. Three 2mm diameter holes were drilled through the longer section .......

..... and three 75mm lengths of 2mm diameter brass rod soldered into the holes. The posts were then glued into 4mm diameter holes dtilled into the edges of the platform.

The whole assembly was then given a couple of coats of Halfords red oxide primer.

Once the primer had set, the sluice gate assembly was then touched up with various shades of brown acrylics and then sealed with a couple of coats of matt varnish.

A layer of concrete, into which had been mixed some black cement dye, was then smeared over the mill stream area to even out some of the inconsistencies in its finish.

Slabs were scribed into the 'green' concrete on top of the wall dividing the main stream from the mill stream..

Once the concrete had set, the sluice gate was tested.

The height of the gate was adjusted using the rack and pinion until the wheel was rotating at what seemed like a reasonable speed.

There seemed to be a compromise between the ideal speed and a slower speed which meant friction would sometimes stop the wheel.

I am pleased with the outcome. The mill seems to fit in well with its surroundings and the sluice gate does an effective job of restricting the flow of water over the wheel.

There is still a little more detailing to be done. I would like to add some general clutter around the mill and maybe a wooden footbridge linking the mill to the mainline trackbed on the opposite side of the stream. Otherwise, the stream and the mill are now more or less complete.

For more information about how I made the stream see - How I constructed the stream

..... I felt that, in real life, the mill stream would have had some sort of sluice gate to control the flow of water on to the wheel.

After sketching a very basic design, I decided to use some offcuts of foamboard for its construction. I did consider using wood (too prone to rotting) and plasticard (too flimsy) but decided the 5mm thickness of the foamboard would give the gate a fairly substantial, chunky appearance.

The first task was to make the lower guides for the sliding gate. Four pieces of 5mm x 60mm and two 18mm x 60mm lengths of foamboard were cut out.

Two of the narrow pieces were glued on to each of the wider pieces, 5.5mm apart to act as guides for the sluice gate

A 30mm x 150mm piece of foamboard was cut out to act as the platform. A 45mm x 5.5 mm slot was cut into the centre of the platform to allow the sluice gate to rise through it.

The sluice guides were glued .....

...... either side of the slot in the platform.

A 85mm x 40mm piece of foamboard was cut out for the sluice gate.

The gate was then slotted into the guides to check it was the right size. A small amount was shaved off the edges to ensure it slid smoothly.

The upper guides for the gate were mades from four 65mm x 5mm and two 70mm x 25mm pieces of foamboard.

These were then glued above the platform and a 25mm x 52mm piece of foamboard glued across the top.

The semi completed sluice gate was then test-fitted into its location to make sure it fitted and also to determine the size and shape of the blanking pieces which were required either side of the gate.

These were cut from offcuts of foamboard and glued either side of the sluice gate guides.

A couple of sets of plastic spur gears and racks were ordered from Technobots.

The rack was detached from the sprue .......

..... and the moulding reduced in depth with a craft knife.

A slot was cut into the platform to accommodate the rack......

...... and the rack was glued to the centre of the sluice gate.

Once the glued had dried, the sluice gate was fitted back into the guides.

A figure of eight link was drilled and filed from a piece of 1mm thick brass shim, 13mm x 5mm with 2mm diameter holes near each end.

2mm diameter brass rod was soldered into the holes.

..... and the excess solder filed smooth.

A small spur gear was positioned behind the crank handle and a pawl fashioned from an offcut of 1mm thick plasticard.

A 5mm diameter brass washer was then soldered on to the other end of the shaft to retain it.

Two 75mm long posts were cut from 4mm diameter brass rod. The lower 20mm of each post was bent through 90 degrees. Three 2mm diameter holes were drilled through the longer section .......

..... and three 75mm lengths of 2mm diameter brass rod soldered into the holes. The posts were then glued into 4mm diameter holes dtilled into the edges of the platform.

The whole assembly was then given a couple of coats of Halfords red oxide primer.

Once the primer had set, the sluice gate assembly was then touched up with various shades of brown acrylics and then sealed with a couple of coats of matt varnish.

A layer of concrete, into which had been mixed some black cement dye, was then smeared over the mill stream area to even out some of the inconsistencies in its finish.

Slabs were scribed into the 'green' concrete on top of the wall dividing the main stream from the mill stream..

Once the concrete had set, the sluice gate was tested.

The height of the gate was adjusted using the rack and pinion until the wheel was rotating at what seemed like a reasonable speed.

There seemed to be a compromise between the ideal speed and a slower speed which meant friction would sometimes stop the wheel.

I am pleased with the outcome. The mill seems to fit in well with its surroundings and the sluice gate does an effective job of restricting the flow of water over the wheel.

There is still a little more detailing to be done. I would like to add some general clutter around the mill and maybe a wooden footbridge linking the mill to the mainline trackbed on the opposite side of the stream. Otherwise, the stream and the mill are now more or less complete.

For more information about how I made the stream see - How I constructed the stream