My experience of railway modelling is rooted firmly in 4mm scale 00 gauge. Hence, I am used to laying yard lengths of Peco flexible track. When I came to venturing into the garden, the thought of bonding together hundreds of short lengths of preformed track made me shudder so I investigated alternatives. The GRS (Garden Railway Specialists) website listed 1.5m lengths of rail and sleeper packs which seemed ideal. I preferred the larger (R3) radius points/turnouts for the main circuit and so opted for Tenmille. Only later did I find that their points were no longer being manufactured.

Tenmille track has a slightly narrower profile than LGB track and needs special rail joiner to link with LGB track. However, it looks good and is easy to lay.

Update 28/8/09

I've since combined LGB, Tenmille and Aristo track in several places (eg See Peckforton Station comes to life) and have found that LGB rail joiners/fishplates are fine for linking together all forms of trackwork - no need for the special Tenmille rail joiners which are a bit of a fiddle to use anyway!

Another Christmas loomed and so this time I discovered 8' lengths of rail and sleeper packs made by Aristocraft could be purchased from OnTracks. I duly purchased a dozen lengths of their product. It arrived by special delivery in an 8' long aluminium tube - for which I'm sure one day I will find a suitable use!

Aristocraft track has more or less the same profile as LGB track though the brass rail is paler in colour. It seems softer than the Tenmille track and hence is easier to bend - though this is a mixed blessing as sometimes it bends too easily and can lead to kinking if you're not too careful. As you can imagine, it's almost impossible to unkink a kinked rail! (eg see Rectifying poorly laid track - Progress Report 15)

Just recently, I have discovered that LGB sell 3m lengths of rail and sleeper packs. These I have ordered and will collect from Bay Models in Carnforth - though I'm not at all certain how they will fit into the car! I will keep you posted as to how this track compares with the others. (See - Peckforton Station comes to Life)

The trackbed comprises standard 4" breeze / hollow concrete blocks laid on their side. I had considered digging shallow trenches, shuttering and filling with concrete, but after laying the retaining walls for the raised beds I had a few breeze blocks left over and they seemed to do the job remarkably well. In addition they can be easily lifted and re-sited should I ever decide to redesign the layout. I have already done this when I decided to extend the stream. The gaps between the blocks are in-filled with cement. I tend to do this by hand (clad in rubber gloves) so the goo can be rammed in with fingers and smoothed off. I am hoping this will deter weeds from growing up between the cracks. I have also used a dry-mix method, brushed into the cracks. I'm not too sure about this method as the mix tends to infiltrate the flower-beds and I'm not too sure what it will do the the Ph of the soil!

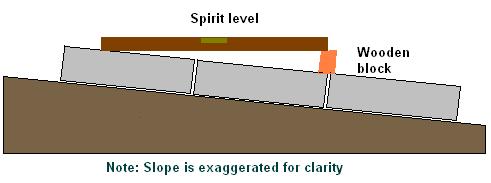

A builder's spirit level was used to ensure each block is level with its neighbour. The gradients were kept uniform by inserting a small block of wood under the lower end of the spirit level. 'Fine tuning' of the position of each block was achieved either by using sifted soil or, when it was available, builders' sand.

I am a little concerned about the durability of the breeze blocks. I appreciate that in time they will crumble as they are attcked by the elements. I am hoping that once the track has been ballasted with chippings held in place, either with a dry cement mix or diluted outdoor PVA adhesive, this will provide a protective surface layer. I'm not too worried if the exposed outer edges weather away - should look more natural.

The track is screwed to the blocks with rawlplugs. I have used either brass or zinc-plated screws - again with the intention of being able to remove the track is necessary.

Great blog, thanks for your efforts.

ReplyDeleteJD in Belgium.

Great blog, many thanks for your efforts.

ReplyDeleteJD in Belgium.

Thanks JD

ReplyDeleteI try to share with others the sort of things I would have liked to have read when I first started in this hobby. I hope there is something which is helpful (even if it's - well, I certainly wouldn't do it like that!)

Rik

Great blog for me too ! Thank you. What do you mean with « standart 4’’ breeze block » ? I’ve red there are many thickness : « The blocks are available in a standard face size of 440 x 215mm and in thicknesses of 75mm, 90mm, 100mm, 140mm and 190mm in a standard finish (suitable for rendering). 100mm, 140mm and 190mm wide blocks are available in close texture finish ». And no ciment or mortar under the blocks ? François from France

ReplyDeleteHi François

ReplyDeleteI'm not sure whether the standard UK concrete breeze block is the same as those in France but the one I was referring to is 215 X 440 X 100mm

https://www.wickes.co.uk/Tarmac-Standard-Dense-Block---7-3N-100mm/p/166859?utm_source=google&utm_medium=cpc&adpos=&scid=scplp166859&sc_intid=166859&gclid=CjwKCAiAl4WABhAJEiwATUnEF0GUZI4FeXlb945qB7a0FBroi6FrDi2kmPDTv49-vT57yQo-SuAjZhoCPRQQAvD_BwE&gclsrc=aw.ds#

Hope that helps

Rik

Try this link - https://www.wickes.co.uk/Tarmac-Standard-Dense-Block---7-3N-100mm/p/166859

ReplyDeleteRik

Hi Rik,

ReplyDeleteThank you for your prompt answer.

I use 500 x 200 x 100 mm hollow concrete blocks. I’ve decided to use the same thickness as yours (100 mm).

One more question please about this important point. You’ve said « The gaps between the blocks are in-filled with cement. I tend to do this by hand (clad in rubber gloves) so the goo can be rammed in with fingers and smoothed off ». But what about under the blocks ? Nothing else except the soil ? Or soil with sand ?

Once more a great blog. I have undertaken to build a garden railway and your advice is very usefull. Thank you.

Hi François

ReplyDeleteI haven't embedded my blocks in concrete, I use sand or sometimes just soil. This means I can easily lift them if/when I want to change the route of the trackbed. However, it does mean the blocks sometimes drop as the soil underneath settles - but that could also happen if they were bedded on concrete.

Rik