Getting started - background research

Having previously constructed a model based on the Southwold Railway 0-6-2T loco Wenhaston (see How I constructed an 0-6-2T loco) I decided that the next addition to my stud would be one of the Southwold's Sharp Stewarts. As these were fairly diminutive locos and I need as much space as I can to house the batteries and radio control equipment, I decided to build the line's slightly larger 2-4-2T loco No.1 Southwold.

The next step was to find a scale drawing. There is one in Vic Mitchell and Keith Smith's Branchline to Southwold (Middleton Press, 1984) and also a more detailed drawing in the January 1979 edition of Model Railway Constructor. I made a photocopy of this drawing and enlarged it as much as I could to fit on to a piece of A4 paper.

As I knew (from the drawing in Branchline to Southwold, that the leading and trailing wheels were 2' diameter, I measured these on the drawing and divided this into 32mm (ie what 2' would be in 16mm:1 foot scale). This turned out to be a ratio of 2.114 and so, by measuring any dimension on the drawing and multiplying that by 2.114, I had its length on my model. I also accumulated as many photos as I could find of the original, as drawings sometimes omit finer details. For example, I discovered on a photo that there was a row of rivets along the base of the bunker rear which are not shown on the drawing.

Firstly it was necessary to dismantle the block. Two screws at the base of the block were removed .......

....... and then the clips at at the top of the block were prised apart .........

......... allowing the motor block to be split.

The electrical pick-ups and skates were removed ........

... and the ends of the motor block were then pared down with a razor-saw.

Wires were then soldered on to the terminals for the motor and passed through a couple of holes drilled into the top of the motor block.

The motor block was then reassembled and tested with a 6 volt battery pack.

A 112mm x 48mm opening was cut into the footplate to accommodate the motor block.

Mounting brackets were then fashioned from 2mm (80thou) plasticard and superglued to the ends of the motor block to support the footplate 39mm above the rails.

Slots were then cut into opening for the wheels and to locate the footplate on the brackets.

The sides were then cut out ........

........ followed by the ends of the cab and the ends of the tanks.

A slot for the fireman to access the coal in the bunker was then cut into the rear of the cab and a representation of the sliding hatch was made from 1mm (40thou) plasticard.

A curved slot was then cut into the cab front to provide space for the boiler.

The cab and tanks were then assembled with liquid poly glue. The backs and the top of the tanks were cut from 1.5mm plasticard and glued into place.

This was then plunged into a bowl of boiling water and left for around five minutes. The process was repeated with a piece of 1mm plasticard .........

........ which gave me two tubular pieces of plasticard ...........

....... which were then glued together with liquid plastic solvent, the 1.5mm as the inner and the 1mm laminate as the outer, making sure the two joins were on opposite sides of the tube.

This was left overnight to ensure the solvent had completely dried out, before a slot was cut into the underside of the boiler the same size as the motor block and battery pack.

The boiler was then test-fitted on to the rest of the body, the clearances were checked and the battery was inserted to ensure there was sufficient space.

A 3.5mm hole was drilled into the shorter end of each bracket and a 3mm bolt was attached to the support brackets for the footplate with a nut either side of the bracket. An additional two nuts were tightened together further down the bolt to act as a locknut giving sufficient space at the lower end to allow the bogie to swing and to flex.

The chassis was then test-run over various piece of track and pointwork to ensure it was OK .......

..... and the body was fitted on temporarily to check clearances.

The buffer beams were then carefully cut out ......

...... and attached to the front and rear of the footplate, together with two 4mm wide strips along each side.

The rear of the bunker was then cut out and glued in place.

After careful measuring, I searched around for something suitable for constructing the cylinders. It turned out that end-feed straight connectors for 15mm copper piping were almost exactly the right size (only 0.5mm too small in diameter).

Discs were cut out from 1mm brass sheet to fit each end of the connectors........

...... and three 2mm holes were drilled in them, one in the centre and the other two 5mm from the centre. For the other end, the disk had only one 2mm hole in the centre.

The disks were then soldered on to the ends of the cylinders.

A piece of 2mm diameter brass tubing was then soldered into the centre hole

After the two other holes were opened out with a square file, two pieces of 2mm brass angle were then soldered into the holes.

The excess solder was then filed down.

A couple 1mm thick disks of plasticard were cut-out for each cylinder, drilled to fit over the ends, and then given cosmetic nuts and bolt heads (from Cambrian Models).

The cosmetic ends were then slipped over the ends of the cylinders and superglued into place. Brass washers were then slipped over the centre tube and superglued into place.

A 18mm x 8mm piece of 1mm brass was cut out and 2mm of each end was folded over, and then another 2mm folded over and a 1.5mm hole drilled in the centre.

It was then filed into a butterfly shape and slipped over the slide bars to form the cross head.

A 1.5mm hole was drilled into the end of a piece of 6mm wide x 1.5mm thick brass strip. This was then filed into shape to form a linkage for the end of the piston rod.

The linkage was then removed and soldered to the end of a piece of 1.5mm diameter brass rod.

To form the connecting rods, two 65mm long pieces of 6mm wide x 1.5mm thick brass strip were marked-out with 8mm sections at each end and longitudinal lines 2mm from each side.

The con-rods were then filed to shape.

After filing to shape the end which will connect with the cross-head, a 1.5mm hole was drilled in that end, and a 4mm hole drilled in the other end. With hindsight, I should have drilled the holes before filing the sides of the con rod as the drilling distorted the ends and they had to be hammered back into shape.

After some experimentation, a countersunk 10BA bolt was passed though the con rod, then the linkage for the piston rod with a washer between. A nut was then threaded on to the bolt, before the crosshead was added followed by another nut. The two nuts were then tightened against each other to form a locknut, allowing the con rod and the piston rod to spin freely.

In the meantime, two steel connecting rods were purchased from Roundhouse which happened to have exactly the right centres (72mm). The holes were opened-out slightly to give a loose fit for the shortened 4mm bolts (see How to shorten bolts - pending) .......

.......... which were then then self-tapped into the plastic wheel centres.

The cylinders were attached to a length of 12mm wide x 1.5mm thick brass strip with self tapping screws.

The ends of the strip were slotted to allow the cylinders to be angled downwards.

The length of the strip was determined by testing various lengths on the R1 curves to see what was the minimum to allow clearance. This means that the cylinders are mounted slightly further out than the prototype but this is a small compromise to ensure the loco will negotiate the sharpest curves on the railway.

The con-rod / crosshead assemblies were then installed on both sides and some testing of the chassis was carried out on a rolling road and in the field to ensure it worked. To support the floating ends of the slide bars, a cross-piece of 6mm wide x 2mm thick brass strip was cut to fit beneath the body.

Two 28mm long x 12mm wide x 1.5mm thick strips were cut out and the top 6mm bent over.

4mm deep slots were cut on one side 3mm, 5mm, 12mm and 15mm from the end.

The gap between the middle slots was then filed out.

The two brackets were then soldered to the ends of the cross piece, the tags were folded over and a 3mm hole drilled and countersunk in the centre of the cross piece.

The cross piece was then bolted to the chassis and the slide bars soldered to the tags on the hanging brackets.

The chassis was then test run again on the rolling road and in the field.

Following the guidance provided on Rod Hayward's Mallet log, a riveting tool was constructed from a piece of 3mm diameter brass rod with a small nail attached as a point and a sliding lead weight attached to provide a measurable 'clonk' to the point.

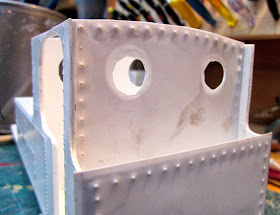

Overlays for the tank and cab sides, cab front, cab rear and bunker rear were marked out and cut from 2 thou (0.5mm) plasticard, with a 2mm additional border around each edge to allow for some manoeuvring when the overlays will be fitted. This is the overlay for the rear of the bunker.

A strip of graph paper, marked at 2mm intervals, was then wrapped around and attached to the plasticard with masking tape .

After counting the rivets and dividing this into the width of the panel, the graph paper was marked off at the appropriate intervals - in this case every 6mm.

Holes were then pricked an appropriate distance from the edge of the panel (in this case 3mm) using the point of a pair of compasses.

The point of the riveting tool was then positioned in the pricked hole (it naturally finds the depression) and the weight raised to a predetermined height (the higher, the larger the rivet), in this case, I raised the weight to within three finger-widths of the top).

To ensure the rows along the sides were in line with the top rivets, a line was drawn between the end rivets and when the graph paper was placed over the panel the pin-pricks were made along this line (the line being visible through the graph paper).

The overlays were then glued on to the relevant body panels with solvent adhesive making sure the rivets are carefully aligned with the edges. Here you can see how the overlay overlaps the edge on the rear of the bunker. Once the adhesive had set, the excess was trimmed off with a craft knife and then smoothed off with a file. Note also, that I missed one rivet on the left edge of the cab back. This will be remedied by gluing a Cambrian rivet head in the gap.

As with the overlays, the beading was trimmed to length once the glue had set.

Beading was also glued into place around the doorways, using the same principles.

The overlay for the cab front was cut to size to fit between the beading and riveted using the above method.

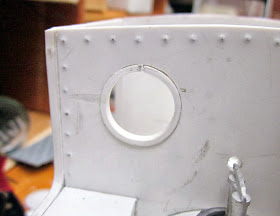

Any gaps and inconsistencies will be filled and smoothed off just before the first coat of primer is applied. The holes for the spectacles in the overlays were then carefully filed to the appropriate size.

The body was then test fitted again on the chassis to check for clearances (and to give me an opportunity to admire my handiwork!).

Strips of gradually increasing width were cut from the roll with a pair of tin-snips.

These were positioned in the top of the boiler until the cavity above the cut-out for the motor block and battery was filled.

A piece of 2mm thick plasticard was then cut out to sit below the weights.

This was glued into place with solvent adhesive and the lead was held in place with clear Uhu type adhesive.

The hole at the front is to accept the lug on the base of the GRS chimney.

Whitemetal boiler fittings (chimney (not shown), dome, safety valve and smokebox door) were purchased from Garden Railway Specialists (GRS).

The based of the fittings were filed with a half-round file to enable them to fit more snugly on the boiler ........

...... before they were glued into place with epoxy (I may eventually make my own more delicately proportioned chimney to replace this one if I can get access to a lathe).

It was then, I realised I should have left an access gap in each tank extension and so had to remove these from the sides of the tanks.

Beneath the tank extension on the left had side, a slot was marked out to accommodate a sub-miniature SPDT slide switch ......

...... which I had purchased from Maplin.

This was then wired-up, with red wires soldered to the middle and one of the other tags .......

..... and heat-shrink insulation was then placed over the connections and shrunk to fit using the heat from a throwaway lighter.

A 2.5mm power socket was then wired-up (two black wires to the -ve terminal and one short red wire to the +ve terminal) .....

.... and then insulated.

The socket was then fitted into an 8mm diameter hole which had been drilled beside the slot for the switch..........

...... and the short red wire was fed through the switch slot.

This wire was then soldered to the other tag on the switch, and insulated.

The switch was then fixed into place with two self-tapping screws.

The red wire from from the other end-terminal of the switch was soldered to the positive lead for the Deltang Rx60 receiver/controller and one of the black wires from the socket was connected to the other lead from the Rx60.

The receiver/controller was then poked into the tank extension.

These were then slotted into the tanks either side of the body.

A piece of 2mm plasticard was cut to shape to hold the battery in place.

After fitting, the two brown wires from the receiver/controller were soldered to the motor leads on the chassis and the receiver was bound to the transmitter (see An evaluation of the Deltang r/c system).

The loco was then test-run to check how the newly added weight affected its running. Fortunately, the weight actually improved its smooth running and enhanced its acceleration and deceleration.

Two short lengths of 4mm diameter earthing cable were cut with the ends suitably stripped ......

...... to form steam pipes. I decided to make these longer than the prototypes as the cylinders on my model are spaced further out (to allow room for the front bogie to swing). Two angled brackets were then added from 1.5mm (60 thou) plasticard as per the prototype.

Finally, a whitemetal smokebox door moulding from GRS was superglued to the front of the loco.

3mm wide strips were cut from a sheet of 2mm (80thou) plasticard.

Using the cable ties from the boiler moulding process, I coiled the strips inside the ties and tightened them .....

........ around a felt tip marker pen which was the same diameter as the spectacles.

These were then dunked in boiling water and left for around ten minutes (the spoons are weighting the felt tip down).

After removal from the felt tip, the 'rings' retained their shape.

Each one was carefully inserted into the hole, trimmed to size and then glued in place with solvent.

Any inconsistencies will be filled after the first coat of primer has been applied.

Two elliptical disks of 1mm (40thou) plasticard were cut out and given a 2mm wide rim from 0.5mm (20thou) plasticard. Another, slightly smaller elliptical disk of 1.5mm thick plasticard was sanded to a domed shape.

A piece of brass rod was bent to form a handle and a small offcut of plasticard formed the hinge.

The fillers were then glued into place in the centre of the tanks.

These were glued together.

In the meantime, another piece of 1.5mm thick plasticard was cut, slightly smaller than the backhead and the firebox door created from various pieces of plasticard.

Further details were added to represent the regulator, water level gauge and a press stud to represent a valve.

The backhead was then glued to the firebox and cosmetic boltheads from Cambrian were added (maybe should have recessed them to represent boiler plugs!).

A steam pressure gauge was made from the end of a cheap metal biro .....

A 1.5mm hole was drilled in the side and it was then flooded with epoxy resin on a scrap of plasticard.

When the resin had set, the plasticard was trimmed to shape. The dial was made by finding a photo of a pressure gauge on the internet and shrinking the photo until the dial was the right size to fit inside the bezel. For fine adjustment of images, I use Microsoft Word. I insert the image and then right click on it. One of the options shown is 'Size'. The image can be adjusted in steps as small as 1/10mm and printed out.

Two pieces of 2mm thick plasticard were then glued along the sides for additional bracing and 1mm wide strips of 0.5mm thick strips were added along the edges. The photos show that the metal used for the roof on the original was extremely thin but the 0.5mm single thickness looked a little too flimsy

A 4mm wide strip of 0.5mm plasticard was then glued across the middle of the roof and trimmed to size.

The cab was then assembled to check it looked OK.

I like the rooves of my locos to be removable so I can add details. I have not yet glued the firebox in place as it will be painted before being finally fixed in place.

It was then filed to shape, before being removed from the rest of the strip, ........

..... and bent to shape.

The steps were then bolted beneath the cab.

The width of the material at the top needed to be wider but I did not have any brass sheet of a suitable thickness to hand. One day, I might replace them with wider alternatives when I next renew my stock of brass sheet.

The wounded shoulder was patched-up with Green-stuff, suitably sculpted.

I did consider having it resting on the regulator but somehow it looked anatomically odd, so in the end I decided he would be puffing on a pipe. This was soldered together from a piece of copper tube and a short piece of brass rod and then inserted into a hole drilled in his fist.

The buffer beams were marked out and the rivets were transferred to their positions using the tip of a scalpel.

Once a few were in position, liquid poly adhesive was applied with a small paintbrush - which sometimes dislodged (or floated) the rivets out of positions, so they were coaxed back into place with the scalpel.

I decided to also reposition the rivets which I had punched on the left-hand cab side. Their original position was far too close to the doorway, so I filed them down and glued an alternative row of rivets into the correct position.

These were removed from their sprue and excess moulding flash removed with a file.

The positions of the knobs were marked out on the sides of the boiler.

..... and 1.8mm diameter holes drilled to take the knobs. The ends of the knobs were coated with superglue before being inserted in the holes.

The same process was repeated for the hand rails either side of the cab

and on the front of the smokebox.

The loco was then taken out into the garden for some test-running to check the couplings were fitted correctly and to see if any of the additions (eg the steps) affected the loco's performance.

Everything seemed fine and so I now moved into the final stages of the build. Before sending her through the paint-shop there were a few more tweaks and adjustments needed.

Daylight beneath the front end of the loco was further masked by adding some cosmetic frames behind the cylinders and behind the leading pony-truck from 20mm wide pieces of 2mm plasticard. Their exact dimensions were dictated by the bracket holding the pony-truck to ensure it was still able to swing round the R1 curves on the railway.

In a similar way, additional frames were added to the rear of the motor block.

Cosmetic overlays from 0.5mm plasticard were formed (as above) ..........

...... and fixed over the cylinders, using superglue.

...... and then smooth these down with varying grades of emery paper, using shaped lolly-pop sticks to reach some of the more awkward nooks and crannies.

I find that running a finder-tip over the surface gives a fairly clear idea as to whether a surface is sufficiently smooth, and then a further smoothing is often seen to be needed once the primer has dried.

........ and three coats of Halford's grey primer were applied to the body from a rattle-can.

The loco was then left for a couple of days for the primer to harden off. Although the instructions suggest that 24 hours is sufficient, I prefer to leave it at least a couple of days as I've found that the primer is sometimes too soft to be sanded down satisfactorily.

Besides, I quite like seeing the loco in her 'Works Grey' finish.

One of the advantages of giving the model a coat of primer is that it shows up blemishes and inconsistencies in the body which need additional rubbing-down and/or filling - as can be seen around the base of the funnel.

I noticed too that the casting for the top of the chimney was damaged. After drilling three 1mm holes to give the filler something to adhere into.......

...... epoxy filler was mixed and applied with a modelling tool.

Once set, the filler was filled into shape.

The cab and the buffer beams were then masked ..........

....... before the model was given a couple of coats of Rover Brooklands Green from a Halfords rattle-can aerosol. This required the model to be sprayed whilst upright and again while inverted to ensure the spray penetrated all the nooks and crannies.

The gloss finish shows even more clearly any imperfections in the bodywork. For example, a slight dent in the top of the side tank .........

.... and here, some roughness on the side of the tank.

These irregularities were carefully rubbed-down with fine grade (1200) emery paper ......

...... using a variety of small wooden blocks.

The loco was then given a final coat.

These were then added to the backhead and painted with Plastikote brass enamel paint.

A GRS whitemetal brake pedestal was then assembled and pointed on a short plastic cone from the end of a toy, left over from making a set of milk churns (see How I made some milk churns). The cone was needed to raise the brake level above the level of the cab sides.

This was then painted with primer and given a coat of black acrylics.

Once the paint had set, the running plate was given a coat of black acrylic.

and the chimney cap, spectacle rings and handrail knobs were given a coat of Plasticote brass enamel.

Lengths of 1.5mm OD brass tube were then slotted into the handrail knobs.

Scrutiny of photos of the original loco revealed that the handrails were finished off with domed caps. Casting around for something to resemble these, I came across a pack of brass escutcheon pins which I'd purchased a while back in the hope they may one day come in handy.

However, the shanks of the pins were too large to fit into the brass tube and so they were filed down .......

........ to around 0.5mm diameter ........

..... so they could be slotted into the ends of the tubes. They were then held in place with a dab of superglue.

The connecting rods and crosshead were given a coat of Plasticote red enamel.

.... and the interior of the cab was painted with cream acrylic paint.

Some of the details on the backhead were picked out in red .......

..... before it was fitted inside the cab along with the pressure gauge.

.... and up into the bunker, before being connected .........

...... to the relevant terminals on the sound card.

The sound card was then slotted into the bunker ..........

..... and the speaker was fixed to the underside of the cab rood with a double sided sticky pad.

The underside of the roof was then given a coat of black acrylic paint to help disguise the protrusion above the head of the driver.

To operate the whistle, I needed to re-program the output from Pad 1 of my Rx60a receiver/controller and add an FET switch. Although this initially sounds quite a daunting process, it is actually quite stratightforward. To reprogram the controller I used Deltang's Prog1 Programma module (see How I used a Prog1 module to reprogram a Deltang receiver) and followed the instructions on the Deltang website to solder together the three components required to make the switch (see How I constructed an transistor switch). I can assure you, my technical and electronical knowledge are fairly basic - it's just a question of following the guidance.

The loco was then tested and progress so far admired.

Unfortunately the weather outside was appalling and so I was unable to take her out and give her some proper test-running which would have enabled me to properly configure the steam soundcard.

To hide the soundcard, an insert for the bunker was constructed from 2mm thick plasticard, together with a wooden lid made from coffee stirrers.

The insert was painted with black acrylics and the lod stained with a wash of brown.

Crushed coal was then sprinkled on to a layer of exterior PVA .........

...... and the insert and lid were then slotted into place over the bunker.

To complete the detailing, oil reservoirs were made from Greenstuff (a two-part epoxy filler) shaped between finger and thumb around the head of a brass escutcheon pin .......

and then painted with Plasticote brass enamel paint.

I have found from experience that wheels from suppliers such as Tenmille, IP Engineering and Accucraft have a finer profile than LGB standards and hence the flanges need to be deepened and widened (see How I improved the compatibility of non LGB wheels with LGB pointwork).

The loco was then test-run extensively and a few minor tweaks made to the running gear to enhance her performance - the cylinders and motion were moved out further to accommodate the front pony truck when negotiating R1 points - and the framing above the pony-trucks was thinned to allow more vertical movement (I found there were depressions in the trackwork on the railway where the pony-trucks were lifting the driving wheels clear of the track!). Now I have constructed one of these locos, I think I could now make an even better model - such is life.

The more experience I gain of constructing model locos, the more I learn. Hopefully, you can see from this posting that I am no expert. If I can do it, I'm sure anyone can. The skills I have used, developed and applied are little more than those needed to construct a kit - but the savings made and the satisfaction gained are considerable. Overall I'd say this model (on the road) has cost me:

Motor block - £35.00 (inc postage)

Plasticard / brass - £20.00

Wheels - £10.00 (ie for pony trucks)

Fittings - £30.00 (eg dome, chimney, smokebox door, etc.)

Paint etc. - £20.00

Subtotal - £115.00

Battery - £15.00

Electrics - £40.00 (inc Deltang receiver/controller)

Sound card + speaker - £60.00

Grand total £230.00

Having previously constructed a model based on the Southwold Railway 0-6-2T loco Wenhaston (see How I constructed an 0-6-2T loco) I decided that the next addition to my stud would be one of the Southwold's Sharp Stewarts. As these were fairly diminutive locos and I need as much space as I can to house the batteries and radio control equipment, I decided to build the line's slightly larger 2-4-2T loco No.1 Southwold.

|

| Source: http://www.southwoldrailway.co.uk/images/sr-1.gif |

As I knew (from the drawing in Branchline to Southwold, that the leading and trailing wheels were 2' diameter, I measured these on the drawing and divided this into 32mm (ie what 2' would be in 16mm:1 foot scale). This turned out to be a ratio of 2.114 and so, by measuring any dimension on the drawing and multiplying that by 2.114, I had its length on my model. I also accumulated as many photos as I could find of the original, as drawings sometimes omit finer details. For example, I discovered on a photo that there was a row of rivets along the base of the bunker rear which are not shown on the drawing.

|

| Source: http://www.southwoldrailway.co.uk/photos/images/SetPhoto43.jpg |

Adapting the motor-block

Knowing my limitations at building successful mechanisms, I spent some time searching around for a suitable motor block. Eventually, I came across a secondhand Playmobil 0-4-0 motor block on the German eBay auction site. The diameter of the wheels and their spacing was close enough to the actual measurements in 16mm scale for the build to go ahead.Firstly it was necessary to dismantle the block. Two screws at the base of the block were removed .......

....... and then the clips at at the top of the block were prised apart .........

......... allowing the motor block to be split.

The electrical pick-ups and skates were removed ........

... and the ends of the motor block were then pared down with a razor-saw.

Wires were then soldered on to the terminals for the motor and passed through a couple of holes drilled into the top of the motor block.

The motor block was then reassembled and tested with a 6 volt battery pack.

The footplate

A piece of 2mm (80thou) plasticard was marked out 90mm x 259mm for the running/footplate.A 112mm x 48mm opening was cut into the footplate to accommodate the motor block.

Mounting brackets were then fashioned from 2mm (80thou) plasticard and superglued to the ends of the motor block to support the footplate 39mm above the rails.

Slots were then cut into opening for the wheels and to locate the footplate on the brackets.

The body shell

The sides of the cab and tanks were then marked out on a piece of 1.5mm (60thou) plasticard.The sides were then cut out ........

........ followed by the ends of the cab and the ends of the tanks.

A slot for the fireman to access the coal in the bunker was then cut into the rear of the cab and a representation of the sliding hatch was made from 1mm (40thou) plasticard.

A curved slot was then cut into the cab front to provide space for the boiler.

The cab and tanks were then assembled with liquid poly glue. The backs and the top of the tanks were cut from 1.5mm plasticard and glued into place.

The boiler

I next turned my attention to the boiler. After scouring the garage and the cupboard under the sink for cylindrical plastic containers of the right diameter (44mm), I drew a blank. The nearest I could find was a piece of 40mm diameter plastic water pipe. I decided to use this as the former to mould some plasticard to the correct diameter tubing. Firstly, a piece of 1.5mm plasticard was cut to the right length and approximately the right width (plus 5mm) and wrapped around the water pipe. It was held in place with cable ties with some wooden coffee stirrers to ensure the ends of the plasticard laid themselves flat against the tube.This was then plunged into a bowl of boiling water and left for around five minutes. The process was repeated with a piece of 1mm plasticard .........

........ which gave me two tubular pieces of plasticard ...........

....... which were then glued together with liquid plastic solvent, the 1.5mm as the inner and the 1mm laminate as the outer, making sure the two joins were on opposite sides of the tube.

This was left overnight to ensure the solvent had completely dried out, before a slot was cut into the underside of the boiler the same size as the motor block and battery pack.

The boiler was then test-fitted on to the rest of the body, the clearances were checked and the battery was inserted to ensure there was sufficient space.

The pony-trucks

In the meantime, I turned my attention to the chassis - more particularly the pony trucks. Two u-shaped brackets were made from 12mm wide x 1.5 mm thick brass sheet with holes drilled to take the axles of the Tenmille spoked wheels, which were the closest match to the leading and trailing wheels (about right in terms of diameter but with too many spokes). Another piece of 12mm wide x 1.5mm thick brass shim was then soldered across the top of the brackets to both act as a pivot and as a bracket for mounting the couplings. The length of this piece was determined by the position of the bogie wheels in relation to the driving wheels and the ends of the chassis (plus 10mm for final adjustment).A 3.5mm hole was drilled into the shorter end of each bracket and a 3mm bolt was attached to the support brackets for the footplate with a nut either side of the bracket. An additional two nuts were tightened together further down the bolt to act as a locknut giving sufficient space at the lower end to allow the bogie to swing and to flex.

..... and the body was fitted on temporarily to check clearances.

Framing the running plate

To give the footplate more rigidity, I deepened it and the running plate by adding buffer beams and side frames. Two rectangles of 2mm plasticard (90mm x 15mm and 90mm x 17mm) were marked out and the curve at each end was drawn by using the handles of a pair of scissors as a a template.The buffer beams were then carefully cut out ......

...... and attached to the front and rear of the footplate, together with two 4mm wide strips along each side.

The rear of the bunker was then cut out and glued in place.

The cylinders and motion

A piece of 2mm thick plasticard was then fashioned and attached to the front of the chassis to support the cylinders and motion. The cut-out for the leading bogie was determined by running the chassis through some R1 LGB curves to ensure there would be sufficient clearance.After careful measuring, I searched around for something suitable for constructing the cylinders. It turned out that end-feed straight connectors for 15mm copper piping were almost exactly the right size (only 0.5mm too small in diameter).

Discs were cut out from 1mm brass sheet to fit each end of the connectors........

...... and three 2mm holes were drilled in them, one in the centre and the other two 5mm from the centre. For the other end, the disk had only one 2mm hole in the centre.

The disks were then soldered on to the ends of the cylinders.

A piece of 2mm diameter brass tubing was then soldered into the centre hole

After the two other holes were opened out with a square file, two pieces of 2mm brass angle were then soldered into the holes.

The excess solder was then filed down.

A couple 1mm thick disks of plasticard were cut-out for each cylinder, drilled to fit over the ends, and then given cosmetic nuts and bolt heads (from Cambrian Models).

The cosmetic ends were then slipped over the ends of the cylinders and superglued into place. Brass washers were then slipped over the centre tube and superglued into place.

A 18mm x 8mm piece of 1mm brass was cut out and 2mm of each end was folded over, and then another 2mm folded over and a 1.5mm hole drilled in the centre.

It was then filed into a butterfly shape and slipped over the slide bars to form the cross head.

A 1.5mm hole was drilled into the end of a piece of 6mm wide x 1.5mm thick brass strip. This was then filed into shape to form a linkage for the end of the piston rod.

The linkage was then removed and soldered to the end of a piece of 1.5mm diameter brass rod.

To form the connecting rods, two 65mm long pieces of 6mm wide x 1.5mm thick brass strip were marked-out with 8mm sections at each end and longitudinal lines 2mm from each side.

The con-rods were then filed to shape.

After filing to shape the end which will connect with the cross-head, a 1.5mm hole was drilled in that end, and a 4mm hole drilled in the other end. With hindsight, I should have drilled the holes before filing the sides of the con rod as the drilling distorted the ends and they had to be hammered back into shape.

After some experimentation, a countersunk 10BA bolt was passed though the con rod, then the linkage for the piston rod with a washer between. A nut was then threaded on to the bolt, before the crosshead was added followed by another nut. The two nuts were then tightened against each other to form a locknut, allowing the con rod and the piston rod to spin freely.

In the meantime, two steel connecting rods were purchased from Roundhouse which happened to have exactly the right centres (72mm). The holes were opened-out slightly to give a loose fit for the shortened 4mm bolts (see How to shorten bolts - pending) .......

.......... which were then then self-tapped into the plastic wheel centres.

The cylinders were attached to a length of 12mm wide x 1.5mm thick brass strip with self tapping screws.

The ends of the strip were slotted to allow the cylinders to be angled downwards.

The length of the strip was determined by testing various lengths on the R1 curves to see what was the minimum to allow clearance. This means that the cylinders are mounted slightly further out than the prototype but this is a small compromise to ensure the loco will negotiate the sharpest curves on the railway.

The con-rod / crosshead assemblies were then installed on both sides and some testing of the chassis was carried out on a rolling road and in the field to ensure it worked. To support the floating ends of the slide bars, a cross-piece of 6mm wide x 2mm thick brass strip was cut to fit beneath the body.

Two 28mm long x 12mm wide x 1.5mm thick strips were cut out and the top 6mm bent over.

4mm deep slots were cut on one side 3mm, 5mm, 12mm and 15mm from the end.

The gap between the middle slots was then filed out.

The two brackets were then soldered to the ends of the cross piece, the tags were folded over and a 3mm hole drilled and countersunk in the centre of the cross piece.

The cross piece was then bolted to the chassis and the slide bars soldered to the tags on the hanging brackets.

The chassis was then test run again on the rolling road and in the field.

Riveting

Attention was then turned to finishing off the body.Following the guidance provided on Rod Hayward's Mallet log, a riveting tool was constructed from a piece of 3mm diameter brass rod with a small nail attached as a point and a sliding lead weight attached to provide a measurable 'clonk' to the point.

Overlays for the tank and cab sides, cab front, cab rear and bunker rear were marked out and cut from 2 thou (0.5mm) plasticard, with a 2mm additional border around each edge to allow for some manoeuvring when the overlays will be fitted. This is the overlay for the rear of the bunker.

A strip of graph paper, marked at 2mm intervals, was then wrapped around and attached to the plasticard with masking tape .

After counting the rivets and dividing this into the width of the panel, the graph paper was marked off at the appropriate intervals - in this case every 6mm.

Holes were then pricked an appropriate distance from the edge of the panel (in this case 3mm) using the point of a pair of compasses.

The point of the riveting tool was then positioned in the pricked hole (it naturally finds the depression) and the weight raised to a predetermined height (the higher, the larger the rivet), in this case, I raised the weight to within three finger-widths of the top).

To ensure the rows along the sides were in line with the top rivets, a line was drawn between the end rivets and when the graph paper was placed over the panel the pin-pricks were made along this line (the line being visible through the graph paper).

The overlays were then glued on to the relevant body panels with solvent adhesive making sure the rivets are carefully aligned with the edges. Here you can see how the overlay overlaps the edge on the rear of the bunker. Once the adhesive had set, the excess was trimmed off with a craft knife and then smoothed off with a file. Note also, that I missed one rivet on the left edge of the cab back. This will be remedied by gluing a Cambrian rivet head in the gap.

Beading

Once the edges had been trimmed, 3mm wide beading cut from 1.5mm thick plasticard was glued to the relevant edges, the curved internal angles being smoothed into shape with the edge of a pencil.As with the overlays, the beading was trimmed to length once the glue had set.

Beading was also glued into place around the doorways, using the same principles.

The beading at the front of cab was run for 15mm along the top edge of the tanks.

Tanks and cab front

The tops of the tanks were cut from 1.5mm thick plasticard with a recess cut out to accommodate the beading.The overlay for the cab front was cut to size to fit between the beading and riveted using the above method.

Any gaps and inconsistencies will be filled and smoothed off just before the first coat of primer is applied. The holes for the spectacles in the overlays were then carefully filed to the appropriate size.

Adding weight to the boiler

At this stage I decided to add weight to the boiler. A roll of lead flashing was purchased from my local builders' merchant. Although quite expensive, from past experience I know that flashing gives a lot of flexibility in tailoring weights to fit nooks and crannies in loco bodies.Strips of gradually increasing width were cut from the roll with a pair of tin-snips.

These were positioned in the top of the boiler until the cavity above the cut-out for the motor block and battery was filled.

A piece of 2mm thick plasticard was then cut out to sit below the weights.

This was glued into place with solvent adhesive and the lead was held in place with clear Uhu type adhesive.

Adding details to the boiler

Boiler bands from 3mm wide, 1mm thick plasticard were then glued into place along the boiler (the smudge midway along the top of the boiler shows where it has been deliberately roughened to give the glue for the dome something to adhere to).The hole at the front is to accept the lug on the base of the GRS chimney.

Whitemetal boiler fittings (chimney (not shown), dome, safety valve and smokebox door) were purchased from Garden Railway Specialists (GRS).

The based of the fittings were filed with a half-round file to enable them to fit more snugly on the boiler ........

...... before they were glued into place with epoxy (I may eventually make my own more delicately proportioned chimney to replace this one if I can get access to a lathe).

Wiring up the electrics

At this point, I decided to wire up the electrics as this would be more difficult once the boiler was fixed into place. The tanks were extended into the cab (with three pieces of 2mm thick plasticard on each side)It was then, I realised I should have left an access gap in each tank extension and so had to remove these from the sides of the tanks.

Beneath the tank extension on the left had side, a slot was marked out to accommodate a sub-miniature SPDT slide switch ......

...... which I had purchased from Maplin.

This was then wired-up, with red wires soldered to the middle and one of the other tags .......

..... and heat-shrink insulation was then placed over the connections and shrunk to fit using the heat from a throwaway lighter.

A 2.5mm power socket was then wired-up (two black wires to the -ve terminal and one short red wire to the +ve terminal) .....

.... and then insulated.

The socket was then fitted into an 8mm diameter hole which had been drilled beside the slot for the switch..........

...... and the short red wire was fed through the switch slot.

This wire was then soldered to the other tag on the switch, and insulated.

The switch was then fixed into place with two self-tapping screws.

The red wire from from the other end-terminal of the switch was soldered to the positive lead for the Deltang Rx60 receiver/controller and one of the black wires from the socket was connected to the other lead from the Rx60.

The receiver/controller was then poked into the tank extension.

Adding weight to the tanks

Twelve pieces of lead flashing (95mm x 40mm) were then cut out together with four 95mm x 30mm pieces .......These were then slotted into the tanks either side of the body.

Fitting the battery

The battery was then wired up - the negative terminal being wired-up to the other black lead on the socket and the red lead from the centre terminal of the switch being soldered to the positive terminal of the battery.A piece of 2mm plasticard was cut to shape to hold the battery in place.

After fitting, the two brown wires from the receiver/controller were soldered to the motor leads on the chassis and the receiver was bound to the transmitter (see An evaluation of the Deltang r/c system).

The loco was then test-run to check how the newly added weight affected its running. Fortunately, the weight actually improved its smooth running and enhanced its acceleration and deceleration.

Detailing

The final stages of completing the model involved adding details. Firstly the smokebox received attention. Two rectangles of plasticard were added either side of the smokebox.Two short lengths of 4mm diameter earthing cable were cut with the ends suitably stripped ......

...... to form steam pipes. I decided to make these longer than the prototypes as the cylinders on my model are spaced further out (to allow room for the front bogie to swing). Two angled brackets were then added from 1.5mm (60 thou) plasticard as per the prototype.

Finally, a whitemetal smokebox door moulding from GRS was superglued to the front of the loco.

The spectacle rings

The next detail to receive attention was the spectacle rings. After drawing a blank searching for washers and brass eyelets of the right dimensions, I decided to use the same approach as I did for forming the boiler.3mm wide strips were cut from a sheet of 2mm (80thou) plasticard.

Using the cable ties from the boiler moulding process, I coiled the strips inside the ties and tightened them .....

........ around a felt tip marker pen which was the same diameter as the spectacles.

These were then dunked in boiling water and left for around ten minutes (the spoons are weighting the felt tip down).

After removal from the felt tip, the 'rings' retained their shape.

Each one was carefully inserted into the hole, trimmed to size and then glued in place with solvent.

Any inconsistencies will be filled after the first coat of primer has been applied.

Tank fillers

Next came the tank fillers. The drawings and photos of loco No.1 provided very little detail as to their design, other than the outline dimensions. The photos suggested they were quite flush with the top of the tanks and so I went for a freelance design.Two elliptical disks of 1mm (40thou) plasticard were cut out and given a 2mm wide rim from 0.5mm (20thou) plasticard. Another, slightly smaller elliptical disk of 1.5mm thick plasticard was sanded to a domed shape.

A piece of brass rod was bent to form a handle and a small offcut of plasticard formed the hinge.

The fillers were then glued into place in the centre of the tanks.

Cab interior

Attention was then turned to the interior of the cab. A piece of 1.5mm thick plasticard was cut to for the backhead, together with a rectangle of 1mm plasticard.These were glued together.

In the meantime, another piece of 1.5mm thick plasticard was cut, slightly smaller than the backhead and the firebox door created from various pieces of plasticard.

Further details were added to represent the regulator, water level gauge and a press stud to represent a valve.

The backhead was then glued to the firebox and cosmetic boltheads from Cambrian were added (maybe should have recessed them to represent boiler plugs!).

A steam pressure gauge was made from the end of a cheap metal biro .....

A 1.5mm hole was drilled in the side and it was then flooded with epoxy resin on a scrap of plasticard.

When the resin had set, the plasticard was trimmed to shape. The dial was made by finding a photo of a pressure gauge on the internet and shrinking the photo until the dial was the right size to fit inside the bezel. For fine adjustment of images, I use Microsoft Word. I insert the image and then right click on it. One of the options shown is 'Size'. The image can be adjusted in steps as small as 1/10mm and printed out.

Cab Roof

The cab roof was tackled next. A rectangle of 0.5mm thick plasticard was cut to size and then braced with 2mm thick plasticard shaped to mirror the curve of the roof.Two pieces of 2mm thick plasticard were then glued along the sides for additional bracing and 1mm wide strips of 0.5mm thick strips were added along the edges. The photos show that the metal used for the roof on the original was extremely thin but the 0.5mm single thickness looked a little too flimsy

A 4mm wide strip of 0.5mm plasticard was then glued across the middle of the roof and trimmed to size.

The cab was then assembled to check it looked OK.

I like the rooves of my locos to be removable so I can add details. I have not yet glued the firebox in place as it will be painted before being finally fixed in place.

Cab steps

Cab steps were next on the agenda. A piece of 12.5mm wide and 1.5mm thick brass strip was marked out.It was then filed to shape, before being removed from the rest of the strip, ........

..... and bent to shape.

The steps were then bolted beneath the cab.

The width of the material at the top needed to be wider but I did not have any brass sheet of a suitable thickness to hand. One day, I might replace them with wider alternatives when I next renew my stock of brass sheet.

The driver

The driver started life as a a farmer, holding a pitchfork - I bought three of them as a job-lot on the internet. The pitchfork was carefully removed and his arm was humanely severed at the shoulder. It was then repositioned.The wounded shoulder was patched-up with Green-stuff, suitably sculpted.

I did consider having it resting on the regulator but somehow it looked anatomically odd, so in the end I decided he would be puffing on a pipe. This was soldered together from a piece of copper tube and a short piece of brass rod and then inserted into a hole drilled in his fist.

Riveting the buffer beams

To enhance the appearance of the buffer beams, I then decided to add rivets. I could have made a 0.5mm overlay but decided instead to use Cambrian Models plastic rivets. These were removed from the sprue with a craft knife.The buffer beams were marked out and the rivets were transferred to their positions using the tip of a scalpel.

Once a few were in position, liquid poly adhesive was applied with a small paintbrush - which sometimes dislodged (or floated) the rivets out of positions, so they were coaxed back into place with the scalpel.

I decided to also reposition the rivets which I had punched on the left-hand cab side. Their original position was far too close to the doorway, so I filed them down and glued an alternative row of rivets into the correct position.

Handrails

I then turned my attention to the handrails. Whitemetal, short handrail knobs were acquired from GRS.These were removed from their sprue and excess moulding flash removed with a file.

The positions of the knobs were marked out on the sides of the boiler.

..... and 1.8mm diameter holes drilled to take the knobs. The ends of the knobs were coated with superglue before being inserted in the holes.

The same process was repeated for the hand rails either side of the cab

The loco was then taken out into the garden for some test-running to check the couplings were fitted correctly and to see if any of the additions (eg the steps) affected the loco's performance.

Everything seemed fine and so I now moved into the final stages of the build. Before sending her through the paint-shop there were a few more tweaks and adjustments needed.

Enhancing the chassis

To improve the rigidity of the extension on the front of the motor block on which the cylinders and motion were mounted, Three 5mm wide pieces of 2mm thick plasticard were glued underneath and then covered with a piece of 0.5mm plasticard to make a box girder. The action of the cranks had been causing the cylinders to flex up and down.Daylight beneath the front end of the loco was further masked by adding some cosmetic frames behind the cylinders and behind the leading pony-truck from 20mm wide pieces of 2mm plasticard. Their exact dimensions were dictated by the bracket holding the pony-truck to ensure it was still able to swing round the R1 curves on the railway.

In a similar way, additional frames were added to the rear of the motor block.

Cosmetic overlays from 0.5mm plasticard were formed (as above) ..........

...... and fixed over the cylinders, using superglue.

Filling

The next stage was to apply filler compound to the most glaringly obvious gaps on the loco body ............ and then smooth these down with varying grades of emery paper, using shaped lolly-pop sticks to reach some of the more awkward nooks and crannies.

I find that running a finder-tip over the surface gives a fairly clear idea as to whether a surface is sufficiently smooth, and then a further smoothing is often seen to be needed once the primer has dried.

Painting

Two coats of red oxide primer were applied by brush to the wheels and extensions to the motor block, leaving the motion clear for now, ..................... and three coats of Halford's grey primer were applied to the body from a rattle-can.

The loco was then left for a couple of days for the primer to harden off. Although the instructions suggest that 24 hours is sufficient, I prefer to leave it at least a couple of days as I've found that the primer is sometimes too soft to be sanded down satisfactorily.

Besides, I quite like seeing the loco in her 'Works Grey' finish.

One of the advantages of giving the model a coat of primer is that it shows up blemishes and inconsistencies in the body which need additional rubbing-down and/or filling - as can be seen around the base of the funnel.

I noticed too that the casting for the top of the chimney was damaged. After drilling three 1mm holes to give the filler something to adhere into.......

...... epoxy filler was mixed and applied with a modelling tool.

Once set, the filler was filled into shape.

The cab and the buffer beams were then masked ..........

....... before the model was given a couple of coats of Rover Brooklands Green from a Halfords rattle-can aerosol. This required the model to be sprayed whilst upright and again while inverted to ensure the spray penetrated all the nooks and crannies.

The gloss finish shows even more clearly any imperfections in the bodywork. For example, a slight dent in the top of the side tank .........

.... and here, some roughness on the side of the tank.

These irregularities were carefully rubbed-down with fine grade (1200) emery paper ......

...... using a variety of small wooden blocks.

The loco was then given a final coat.

Superdetailing

While the paint was drying, I worked on further detailing the cab interior, starting with the boiler backhead. A selection of metal press-studs had their centres drilled-out with a 1mm drill and a short length of 1mm brass rod was then soldered into the hole.These were then added to the backhead and painted with Plastikote brass enamel paint.

A GRS whitemetal brake pedestal was then assembled and pointed on a short plastic cone from the end of a toy, left over from making a set of milk churns (see How I made some milk churns). The cone was needed to raise the brake level above the level of the cab sides.

This was then painted with primer and given a coat of black acrylics.

Once the paint had set, the running plate was given a coat of black acrylic.

and the chimney cap, spectacle rings and handrail knobs were given a coat of Plasticote brass enamel.

Lengths of 1.5mm OD brass tube were then slotted into the handrail knobs.

Scrutiny of photos of the original loco revealed that the handrails were finished off with domed caps. Casting around for something to resemble these, I came across a pack of brass escutcheon pins which I'd purchased a while back in the hope they may one day come in handy.

However, the shanks of the pins were too large to fit into the brass tube and so they were filed down .......

........ to around 0.5mm diameter ........

..... so they could be slotted into the ends of the tubes. They were then held in place with a dab of superglue.

The connecting rods and crosshead were given a coat of Plasticote red enamel.

.... and the interior of the cab was painted with cream acrylic paint.

Some of the details on the backhead were picked out in red .......

..... before it was fitted inside the cab along with the pressure gauge.

The sound card

The wiring for the MyLocoSound steam card was tackled next. I decided that the coal bunker was the ideal location for the sound card and so the wiring needed for the sound card (power supply, connection to the motor, whistle trigger and speaker wires were run beneath the cab............ and up into the bunker, before being connected .........

...... to the relevant terminals on the sound card.

The sound card was then slotted into the bunker ..........

..... and the speaker was fixed to the underside of the cab rood with a double sided sticky pad.

The underside of the roof was then given a coat of black acrylic paint to help disguise the protrusion above the head of the driver.

To operate the whistle, I needed to re-program the output from Pad 1 of my Rx60a receiver/controller and add an FET switch. Although this initially sounds quite a daunting process, it is actually quite stratightforward. To reprogram the controller I used Deltang's Prog1 Programma module (see How I used a Prog1 module to reprogram a Deltang receiver) and followed the instructions on the Deltang website to solder together the three components required to make the switch (see How I constructed an transistor switch). I can assure you, my technical and electronical knowledge are fairly basic - it's just a question of following the guidance.

More detailing

Two whitemetal clack valves from GRS were primed and then painted before being fitted either side of the boiler, as per the prototype.The loco was then tested and progress so far admired.

Unfortunately the weather outside was appalling and so I was unable to take her out and give her some proper test-running which would have enabled me to properly configure the steam soundcard.

To hide the soundcard, an insert for the bunker was constructed from 2mm thick plasticard, together with a wooden lid made from coffee stirrers.

The insert was painted with black acrylics and the lod stained with a wash of brown.

Crushed coal was then sprinkled on to a layer of exterior PVA .........

...... and the insert and lid were then slotted into place over the bunker.

To complete the detailing, oil reservoirs were made from Greenstuff (a two-part epoxy filler) shaped between finger and thumb around the head of a brass escutcheon pin .......

These were mounted on the running plate either side of the boiler.

A few additional whitemetal extras, such as a bucket and the driver's tea flask (from GRS) and a re-railing jack (from Roundhouse) were primed and painted and added, using contemporary photos to guide their positioning.

Finally, the profiles of the Tenmille pony truck wheels were thickened and deepened with 1.5mm plasticard to improve their compatibility with LGB pointwork.

[Awaiting photo]

I have found from experience that wheels from suppliers such as Tenmille, IP Engineering and Accucraft have a finer profile than LGB standards and hence the flanges need to be deepened and widened (see How I improved the compatibility of non LGB wheels with LGB pointwork).

The loco was then test-run extensively and a few minor tweaks made to the running gear to enhance her performance - the cylinders and motion were moved out further to accommodate the front pony truck when negotiating R1 points - and the framing above the pony-trucks was thinned to allow more vertical movement (I found there were depressions in the trackwork on the railway where the pony-trucks were lifting the driving wheels clear of the track!). Now I have constructed one of these locos, I think I could now make an even better model - such is life.

The more experience I gain of constructing model locos, the more I learn. Hopefully, you can see from this posting that I am no expert. If I can do it, I'm sure anyone can. The skills I have used, developed and applied are little more than those needed to construct a kit - but the savings made and the satisfaction gained are considerable. Overall I'd say this model (on the road) has cost me:

Motor block - £35.00 (inc postage)

Plasticard / brass - £20.00

Wheels - £10.00 (ie for pony trucks)

Fittings - £30.00 (eg dome, chimney, smokebox door, etc.)

Paint etc. - £20.00

Subtotal - £115.00

Battery - £15.00

Electrics - £40.00 (inc Deltang receiver/controller)

Sound card + speaker - £60.00

Grand total £230.00

Very impressed. Excellent modelling and very useful write up for us beginners!

ReplyDeleteThanks Dave. I still regard myself as a beginner. I've found the best way to learn is to get stuck-in and have a go - nothing like learning from experience. I've borrowed the expression "Trial and improvement" rather than "Trial and error" - which sums up my philosophy.

ReplyDeleteRik

I am inspired by your work. In the mid 80's I started work on a layout of Southwold station in O Gauge. I got as far as building an O Gauge Southwold Sharp Stewart 2-4-0 in brass plus a coach and wagon that still remain unfinished awaiting patterns for moulds for various castings (Axle boxes etc). Once the children have flown maybe I will get going again. Looking at your work I hope the day is not so far off when I can start again.

ReplyDeleteATB - Mark

Thanks Mark

ReplyDeleteAll the best with completing your build - it sounds a lot more realistic than my version which is a bit of a compromise between what was available and the drawing. However, she looks the part. Maybe you should start a blog on your model building. It sounds as if others (including me) could learn from your experiences - and it would provide a good incentive for you to keep a project going.

Only going to convert a loco to battery remote control and sound. However, I am inspired by your blog to consider something more ambitious. This is certainly the way to get UK outline locos for g scale.

ReplyDeleteI wish you all the best with your efforts. My first proper scratchbuild was my Fowler diesel - http://riksrailway.blogspot.com/2011/04/how-i-converted-playmobil-diesel-into.html . I figured that it was basically just a couple of boxes (cab and bonnet) and so would be easier to build than a steam outline loco. I have tried making my own mechanisms but not very successfully - so base the majority of my builds round commercial motor blocks which, as you'll have seen from some of my videos, as quite powerful.

ReplyDeleteRik

I've been building my own locos for a while, but I have to say that this is one of the best write-ups I've seen on how to build a model steam locomotive.

ReplyDeleteThanks Anne / Annie(?)

ReplyDeleteI seem to recall seeing some of your builds on the GSM forum. Seeing what others have done is what gave me the courage to have a go myself. Great to hear that my offerings have been well received.

Rik

This has definitely inspired me to take the leap to build locos of my own (I'm thinking three 2-4-0 Southwold Sharpies and two Eskdale Manning Wardle 0-6-0s)

ReplyDeleteDelighted to hear it. Sounds like it's going to be an interesting railway with that lineup of motive power. Are the Sharpies going to represent all three on the Southwold? I do like the look of the 3' gauge Eskdale locos but don't know much about them. Did the second loco actually run? I wonder what happened to them after the 3' line closed.

ReplyDeleteI'm thinking of investigating the Rye and Camber Bagnalls next - if I can track down a decent chassis on which to base the build.