Last year, I decided to abandon DCC track power in favour of battery power (see Getting started with battery power). Until then, I had constructed five locomotives from kits or as scratchbuilds, mostly based around LGB 0-4-0 ToyTrain motor blocks. These were used to power such locos as Otto, OHO, Rusty or the ToyTrain diesel which often form the motive power for LGB Starter Sets.

The first kitbuilt loco on my railway was based on the Peckett kit from Garden Railway Services (GRS) (see How I constructed a Peckett loco from a GRS kit).

After removing the body from the motor block, the DCC decoder was disconnected from the track contacts and the motor, basically the reverse of fitting the decoder (see Chipping a ToyTrain motor block).

I then turned my attention to removing the track pick-ups from the chassis. The baseplate of the chassis was removed by unscrewing four screws.

This revealed the pick-up arrangement.

The skates and their brass contacts were removed. These are a push-fit.

The connecting wires were then removed, again these simply slot into the chassis.

Finally, the spring-loaded carbon brushes were removed. These were prised from their recesses with a small flat-bladed screwdriver.

Now that all vestiges of the pick-up system had been removed .........

The base plate was then screwed back into place. It was important to check that the front and rear wheels are carefully aligned (ie the crank pins are in exactly the same position on each set of wheels). I've found from past experience that if they are even slightly out of alignment, the loco runs erratically.

I then had to decide where to install the batteries. If I had opted for battery power while making the kit, I would probably have inserted the batteries into the boiler and/or saddle tank, but these had been filled with lead weights and then sealed. To remove the weights would have required extensive dismantling and rebuilding, so I looked elsewhere for some spare space. The inside of the cab looked promising and so I experimented with slotting three 18650 lithium-ion batteries into various nooks and crannies.

Two fitted in beside the firebox ..........

..... and the third could be suspended from the cab roof.

I used BluTak to hold them in position until a more permanent method could be found for mounting them. I prefer to use ready-tagged batteries to which I can solder leads. I have heard that it is possible to solder leads directly to the ends of batteries such as these, but given the volatility of li-ion batteries, I'd rather not take the risk of applying too much heat to them. Having worked out their relative positions, I soldered leads which would enable them to be connected in series, with two additional wires (the yellow and the blue) connected to the intervening positive terminals which will lead to the battery monitor module. All connections were shrouded in heat shrink tubing to avoid accidental short circuit.

A disadvantage of ready-tagged li-ion batteries is that I have been unable to find any which include 'protection'. Protected batteries include electronic circuitry which prevents them from short circuit and over-discharging, both of which are bad news for li-ion batteries. However, I found some inexpensive circuit boards on eBay which not only protect li-ion batteries in this way, they also monitor the charging of up to four batteries, to ensure each is balance charged correctly.

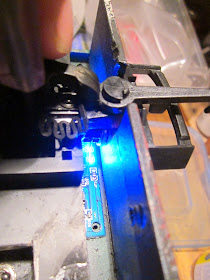

I invested in some of these boards, one of which I installed beneath the cab on this loco using a couple of double-sided sticky pads.

Before wiring-up the board and batteries, I installed the charging power socket in the rear buffer-beam, making sure the contacts were clear of the board.

I then decided where the power switches should be installed - one master switch and the other to power-up the sound card when (and if) one is installed. There seemed to be room on the cab floor for the two switches and so two 8mm holes were drilled for them. I found, however, that 3mm thick plasticard was too thick for the threaded ferrules of the switches and so I reamed out a depression with my mini-drill.

The two switches SPDT (single pole, double throw) switches were then wired-up, the terminals being covered in shrink-wrap tubing.

If you are not familiar with shrink-wrap tube, it is bought in bundles of various diameters.

Suitable lengths are snipped from the bundle and slipped over connections, then heat is applied (I use the flame from a disposable lighter wafted underneath). The tubing shrinks to half its original size, providing a neat and tight layer of insulation around the joint.

I then installed the switches and wired-up the battery protection board to the batteries and switches, and to the recharging socket.

To facilitate the separation of the body from the motor block for maintenance and so on, I like to use some sort of plug and socket system. A bulk-purchase of some brass bullet connectors from eBay furnished me with connectors and insulation sleeves. Two male connectors were soldered to the motor leads on the chassis. A notch was cut into the footplate of the chassis, to accommodate the switches, and the rear buffer beam was removed to allow the power-level LEDs on the protection board to be seen (see below).

Two female connectors were soldered to the motor leads on a Deltang Rx65b receiver/controller. An additional two wires were soldered which will be used at a later date when/if a sound card is installed.

The power leads to the receiver/controller were then soldered into the existing circuitry (see wiring diagram above) ........

...... and covered in shrink-wrap tubing.

The bullet connectors were then connected and the leads and receiver tucked away inside the body.

The loco was reassembled. By pushing a small screwdriver through a hole drilled in the chassis footplate, I can press the button on the protection-board which illuminates the power-level LEDs on the board. These give an indication as to how much the batteries are discharged.

The loco was then given a few test-runs to check everything was operating as intended.

When putting the loco under maximum load, I found the gears slipped. I had noticed when removing the pick-ups from the motor block that the worm wheels were well worn (see above photos) and so decided to replace them. Fortunately, I had a brand new motor-block to hand and I decided that, rather than just replacing the wheels, I'd replace the whole motor block - the new one was manuafctured in Germany whereas the previous one was manufactured in Korea and I know from experience that the German motor blocks are better quality.

The motion was removed from the old motor block which was then modified to fit. It was then fixed in place and tested once more.

To ensure that she was functioning as intended, I gave her a thorough and punishing set of test runs, on a day when the sun was shining.

In response to some enquiries on forums, I decided to do a continuous run to see how long the batteries last. I ran the loco with a train of eight wagons continuously for 5 hours and 20 mins before the protection board cut the power.

Apologies about the blurred images but these were taken as dusk was falling about four hours into the test.

I have also found that the protection board seems to cut the power if the batteries are charged at anything over 0.5A which seems peculiar as the blurb for the boards indicates the maximum charge current is 8A.

I still have another two track-powered locos to convert - a Hunslet, built from a GRS kit, and a scratchbuilt Fowler diesel. Both these locos have less space inside than this loco and so will present their own challenges when it comes to finding space for batteries. However, li-ion batteries now come in all sorts of shapes and sizes and so I am confident I will somehow solve these problems.

The first kitbuilt loco on my railway was based on the Peckett kit from Garden Railway Services (GRS) (see How I constructed a Peckett loco from a GRS kit).

After removing the body from the motor block, the DCC decoder was disconnected from the track contacts and the motor, basically the reverse of fitting the decoder (see Chipping a ToyTrain motor block).

I then turned my attention to removing the track pick-ups from the chassis. The baseplate of the chassis was removed by unscrewing four screws.

This revealed the pick-up arrangement.

The skates and their brass contacts were removed. These are a push-fit.

The connecting wires were then removed, again these simply slot into the chassis.

Finally, the spring-loaded carbon brushes were removed. These were prised from their recesses with a small flat-bladed screwdriver.

Now that all vestiges of the pick-up system had been removed .........

The base plate was then screwed back into place. It was important to check that the front and rear wheels are carefully aligned (ie the crank pins are in exactly the same position on each set of wheels). I've found from past experience that if they are even slightly out of alignment, the loco runs erratically.

I then had to decide where to install the batteries. If I had opted for battery power while making the kit, I would probably have inserted the batteries into the boiler and/or saddle tank, but these had been filled with lead weights and then sealed. To remove the weights would have required extensive dismantling and rebuilding, so I looked elsewhere for some spare space. The inside of the cab looked promising and so I experimented with slotting three 18650 lithium-ion batteries into various nooks and crannies.

Two fitted in beside the firebox ..........

I used BluTak to hold them in position until a more permanent method could be found for mounting them. I prefer to use ready-tagged batteries to which I can solder leads. I have heard that it is possible to solder leads directly to the ends of batteries such as these, but given the volatility of li-ion batteries, I'd rather not take the risk of applying too much heat to them. Having worked out their relative positions, I soldered leads which would enable them to be connected in series, with two additional wires (the yellow and the blue) connected to the intervening positive terminals which will lead to the battery monitor module. All connections were shrouded in heat shrink tubing to avoid accidental short circuit.

A disadvantage of ready-tagged li-ion batteries is that I have been unable to find any which include 'protection'. Protected batteries include electronic circuitry which prevents them from short circuit and over-discharging, both of which are bad news for li-ion batteries. However, I found some inexpensive circuit boards on eBay which not only protect li-ion batteries in this way, they also monitor the charging of up to four batteries, to ensure each is balance charged correctly.

I invested in some of these boards, one of which I installed beneath the cab on this loco using a couple of double-sided sticky pads.

Before wiring-up the board and batteries, I installed the charging power socket in the rear buffer-beam, making sure the contacts were clear of the board.

I then decided where the power switches should be installed - one master switch and the other to power-up the sound card when (and if) one is installed. There seemed to be room on the cab floor for the two switches and so two 8mm holes were drilled for them. I found, however, that 3mm thick plasticard was too thick for the threaded ferrules of the switches and so I reamed out a depression with my mini-drill.

The two switches SPDT (single pole, double throw) switches were then wired-up, the terminals being covered in shrink-wrap tubing.

If you are not familiar with shrink-wrap tube, it is bought in bundles of various diameters.

Suitable lengths are snipped from the bundle and slipped over connections, then heat is applied (I use the flame from a disposable lighter wafted underneath). The tubing shrinks to half its original size, providing a neat and tight layer of insulation around the joint.

I then installed the switches and wired-up the battery protection board to the batteries and switches, and to the recharging socket.

|

| Wiring diagram (Click to enlarge) |

Two female connectors were soldered to the motor leads on a Deltang Rx65b receiver/controller. An additional two wires were soldered which will be used at a later date when/if a sound card is installed.

The power leads to the receiver/controller were then soldered into the existing circuitry (see wiring diagram above) ........

...... and covered in shrink-wrap tubing.

The bullet connectors were then connected and the leads and receiver tucked away inside the body.

The loco was reassembled. By pushing a small screwdriver through a hole drilled in the chassis footplate, I can press the button on the protection-board which illuminates the power-level LEDs on the board. These give an indication as to how much the batteries are discharged.

The loco was then given a few test-runs to check everything was operating as intended.

When putting the loco under maximum load, I found the gears slipped. I had noticed when removing the pick-ups from the motor block that the worm wheels were well worn (see above photos) and so decided to replace them. Fortunately, I had a brand new motor-block to hand and I decided that, rather than just replacing the wheels, I'd replace the whole motor block - the new one was manuafctured in Germany whereas the previous one was manufactured in Korea and I know from experience that the German motor blocks are better quality.

The motion was removed from the old motor block which was then modified to fit. It was then fixed in place and tested once more.

To ensure that she was functioning as intended, I gave her a thorough and punishing set of test runs, on a day when the sun was shining.

In response to some enquiries on forums, I decided to do a continuous run to see how long the batteries last. I ran the loco with a train of eight wagons continuously for 5 hours and 20 mins before the protection board cut the power.

Apologies about the blurred images but these were taken as dusk was falling about four hours into the test.

I have also found that the protection board seems to cut the power if the batteries are charged at anything over 0.5A which seems peculiar as the blurb for the boards indicates the maximum charge current is 8A.

I still have another two track-powered locos to convert - a Hunslet, built from a GRS kit, and a scratchbuilt Fowler diesel. Both these locos have less space inside than this loco and so will present their own challenges when it comes to finding space for batteries. However, li-ion batteries now come in all sorts of shapes and sizes and so I am confident I will somehow solve these problems.

Very interesting blog!!

ReplyDeleteCould you please give a link to the Li Ion protection board you used?

Thanks,

There are lots of different types on eBay. I can't find the specific ones I used but if you search for "3S lithium protection board" you will get this sort of product - - http://www.ebay.co.uk/itm/181874759764 NOTE this URL will become defunct after a while.

ReplyDeletehi sorry to be a bother,

ReplyDeletewhich charging port did you use when you converted the loco as you've given me inspiration to make my own rc loco creation for indoor or outdoor use if I try and may visit any garden railways in the near future.

Kind Regard Josh

Hi Josh. I use standard 5.5mm X 2.1mm DC sockets. They are quite cheap on eBay - around £0.60GBP.

ReplyDeleteRik

Hi Wilson

ReplyDeleteThanks for the feedback.

To answer your question in a word - No! You can get protection boards which monitor the charging process but the are larger and more expensive. The chemistry of lithium cells means they have to be charged with a dedicated charger otherwise you could damage the cells or, worse, run the risk of causing a thermal runaway (ie a fire).

I use an IMax B6 charger. They can charge most types of battery pack and allow you to select your preferred charge rate. The charger can seem a bit daunting when it arrives but it doesn't take long to work out how to use it. I've produced a beginners' guide - https://riksrailway.blogspot.com/2017/05/quick-introduction-to-imax-b6-charger.html

Rik

Hi, thanks for posting this. "Great help" Just started on an Otto & going down the route of fitting running lights with a new one at the rear & converting the head lamp. Plus a new cab light. I am also putting sound a card in & 2 banks of 14.8 battery's all fitted in a wagon towed behind as there is so much more room for everything, including a good 75mm speaker.

ReplyDeleteHi Barnet

ReplyDeleteI've used 3S (ie 11.1v) li-ion packs in all my locos and found that to be plenty of power. I don't tend to run my locos at express train speeds and so a 3S keeps the speeds manageable.

Rik