The LGB Stainz was my first G Scale loco. I well remember sitting on the train on my way back to London clutching the LGB Starter Set, after a trip to Garden Railway Specialists (GRS) in Princes Risborough. Although the Stainz is not a UK outline loco, I have kept her over the past twelve years or so, for nostalgic reasons - and also because she is a fine looking loco. However, as my railway is no longer track powered and my loco roster is exclusively battery powered and radio controlled I decided it was time for the Stainz to join the fleet once more.

The LGB Stainz was my first G Scale loco. I well remember sitting on the train on my way back to London clutching the LGB Starter Set, after a trip to Garden Railway Specialists (GRS) in Princes Risborough. Although the Stainz is not a UK outline loco, I have kept her over the past twelve years or so, for nostalgic reasons - and also because she is a fine looking loco. However, as my railway is no longer track powered and my loco roster is exclusively battery powered and radio controlled I decided it was time for the Stainz to join the fleet once more.Because I enjoy shunting manoeuvres and trains on my railway often run end-to-end, from one terminus to the other, I have tended to avoid using battery trail cars. However, the Stainz loco is an ideal candidate for conversion to battery power by those considering having a battery loco to run on days when they can't be bothered to clean the track. On the back of the Stainz is a small two pin socket which can be used for providing a power output for coach lighting. It can also be used to input power to drive the loco.

The socket is normally hidden beneath a flap moulding ........

....... which simply pulls out.

I discovered that the 2.5mm, JST-XH two pin plug (available from RC Trains) fitted the socket perfectly ....

.... and so, all I needed was a source of power and control.

Dismantling the Stainz

Before working on the trail car, I needed to dismantle the Stainz to remove the LGB MTS loco decoder which I had previously installed. Dismantling can look very daunting as the loco is actually very cunningly constructed, however having already discovered how it was done when I installed the decoder in 2008, I was able to follow my own instructions - see How I chipped a Stainz.With the Stainz in pieces, I could unplug the decoder from the circuit board ......

..... and reset all the DIP switches to 'on'.

Replacing the bulbs with LEDs

In reality, I did this after I had made the trail car and converted the loco to battery power - however, as this entailed reassembly, disassembly and re-reassembly, in hindsight it would have been better to have made the modifications at this point. Those who intend following in my footsteps as a result of this blog posting can hopefully benefit from my experience.On the circuit board are three 47ohm ¼W resistors. These are used to restrict current to the bulbs, presumably to help the bulbs last longer.

As my conversion would be using a 12 volt power pack, I needed to increase the value of the resistors to limit the current to the diodes to under 20mA. A quick calculation on the LEDcalc website revealed that the value of the resistors should be 680ohms for a 12v supply.

The resistors were carefully prised off the board with a prodder and the application of a soldering iron.

The resistors were then replaced with three ¼W 680ohm resistors, which were soldered to the same connections on the board

The loco was then re-assembled.

The front lamp bulb was the easiest to replace. The grain of wheat bulb was eased out of its holder and a 3mm white LED was inserted in its place.

The interior bulb was a little more fiddly to replace as it was tucked away inside the cab.

This bulb lights up only when the loco moves forward. I could have created a diode bridge to ensure it remained illuminated in both directions but decided it wasn't that important.

For a while, the disassembly of the rear lamp baffled me. Consultation of various sources on the web led to conflicting information. Eventually, by chance, I discovered that the lens can simply be prised off with a scalpel blade.

The white reflector was then removed.

This made insertion of the LED a lot easier. Again, I was fortunate to insert it correctly the first time, but it would have been easy to remove it, rotate it and replace it.

The lamp was then reassembled.

Removing the track pick-ups

As I no longer user track power, the pickups were no longer needed. I have found from past experience that removing the wheel contacts and the skates improves the performance of battery locos as it reduces friction.NOTE: It is possible to remove the pick-ups and skates without extracting the motor block from the chassis. If you want to do this ignore this section and skip down the page to section on dismantling the motor block.

The motor block was extracted from the chassis, by removing the couplings .....

.... and then the four screws which fix the block to the chassis.

The two small screws holding the valve gear to the chassis were then removed .....

..... and then the bracket pulled out over the running plate ........

..... to allow the motor block to be removed.

The plug connecting the motor and pick-ups to the main body was then removed from its socket ....

Dismantling the motor block

The four screws holding the baseplate to the block were unscrewed .......... and the cover removed.

The bus-bars were then removed. These simply pull out.

The skates were then removed .......

...... and the brass contacts removed.

To remove the wheel contacts, the wheels were lifted out from their housings.......

..... enabling the pick-ups to be prised out with a flat-bladed screwdriver.

The wheels were then re-inserted, making sure that the coupling-rods were carefully re-aligned. I have found from experience that if they are out by even one cog on the gear wheel, then the loco will not run smoothly. I decided to give the gears some lubrication whilst I had access to them.

The baseplate was then screwed back into place on the motor block.

The block was then returned to the chassis - using the reverse process to dismantling.

The trail car

I could have used an open wagon, with a tarpaulin cover or even a shunting trolley.

I firstly assembled all the bits and pieces I needed - an RC Trains Rx65b receiver/controller, a 2.1mm DC power socket, a single pole double-throw (SPDT) switch, a 2A polyswitch and a 10 AA-cell battery holder (all available from RC Trains).

A piece of 3mm thick clear acrylic sheet was chosen for the baseboard and the equipment laid out on it to determine the size - 70mm x 110mm. Eight 3mm diameter holes were drilled to enable the components to be fixed in place.

A 25mm x 50mm piece of 2mm brass sheet was cut and holes drilled for the charge socket (7.5mm diameter) and the switch (6.5mm diameter). Holes (3mm diameter) were also drilled for the mounting screws.

The mounting bracket was then folded (15mm from the base).

Ten NiMh rechargeable batteries were inserted into the battery holder........

...... which was then fixed in place using cable ties so that it could be readily removed should I need to replace the batteries. At some point in the future I will replace these bog-standard NiMhs with Low Self Discharge (LSD) versions which hold their charge when stored. Nothing is more frustrating than taking a loco out from storage and finding the batteries are flat!

The mounting bracket was fixed in place beside the battery box ........

..... using 6BA (2.5mm) bolts and nuts.

A label was printed out, using vinyl self-adhesive printer film (from Crafty Computer Paper).

The charge socket and switch were then mounted to the bracket ........

....... before everything was wired-up .........

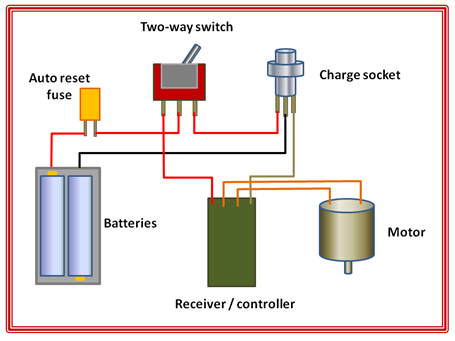

........ using my usual wiring circuitry.

The assembly was then inserted into the van, .........

...... and the output from the receiver/controller connected to the 2.5mm JST-XH plug, which was mounted through a hole in the end of the van.

The roof was then placed back on the van, making sure the switch and charge socket were positioned opposite the sliding door of the van.

The van was coupled to the loco and the plug inserted into the socket.

The loco was then tested ........

The Stainz motor block is extremely smooth-running and responds very well to the 12v supply from the RC Trains Rx65b receiver/controller ......

For now, I am pleased to have my 'Old Faithful' Stainz loco back in action. In time though, I may install li-ion batteries into the cab and do away with the trail car so she can perform shunting duties and run round trains without tugging the van behind her.