This year I have had fewer opportunities than in previous years to run trains on the railway. Firstly, the weather has been very changeable which has meant that there have been relatively few days when an unbroken spell of decent weather could be guaranteed. On a couple of occasions, I had spent an hour or so setting up the railway, only to have to gather everything together and dash back indoors as a shower of heavy rain blew up. Secondly, I have spent several days during the summer period visiting full-scale narrow gauge railways for a new blog which I have set-up (see Narrow Gauge Railways UK). Mostly, these visits seem to have coincided with a spell of decent weather which I could have used for running the railway.

Thirdly, I have spent quite a bit of the summer, doing running repairs, constructing signals, making a set of buildings for the copper mine and experimenting with radio control (see below).

Another issue associated with LGB pointwork which I have uncovered over the seven years I've been running my railway has been a steady and consistent breakdown in electrical continuity between the running rails, point-blades and lead-rails before and after the frogs. I could have removed every point and soldered invisible connections beneath the rails and sleepers, but when I have done this in the past it has caused more problems than it solved. Consequently, I opted for an in-situ solution of soldering jumper wires from the stock rails to the switch rails.

For more information see - How I repaired LGB pointwork

Using the signalling diagrams which were provided by a fellow modeller who also happens to be a Railtrack signalman (see Progress Report 36) ........

......... I figured that even the most minimal approach to signalling the railway would require 20 signals (around 4 per station). I explored various kit-built options but decided that the cost would be prohibitive. I had no option but to construct my own signals.

Although the signals were of the same basic design as I wanted to batch-produce them, there were two alternatives in terms of the types of base. One type had a plate base for mounting on hard surfaces, while the other had a concrete base, for mounting in soft surfaces .......

All the signals are equipped with flickering LED lamps..........

....... which are shuttered at the rear.

At present, the signals are operated individually but eventually I hope to have them operated through linkages to a ground frame at each station, as per prototype.

For details of construction see Garden Rail edition 224 (April 2013).

Ever since the extension to Beeston Market and the copper mine was constructed (see How I built the extension), I have been planning to add some buildings and loading hoppers.

At this stage, construction is well under way - with a variety of techniques being deployed.

A chance-find on eBay resulted in the purchase of a couple of cheap 2.4GHz radio transmitters designed to be used with low-cost helicopters.

I discovered that the transmitters worked with cheap FlySky receivers and so, after setting-up a test-rig, I explored the potential of this cost-effective approach to radio control.

As you can see from the video, with the modest outlay I'm figuring it's worth producing a small fleet of battery-operated locos to run alongside and maybe eventually replace the track powered locos. I have a couple of spare ToyTrain loco blocks which can be pressed into service and one day I will get around to converting my LGB 0-6-2 U-Class Zillertalbahn loco into a representation of the Southwold Railway loco No. 4 Wenhaston.

|

| Orenstein & Koppel 0-4-0 locos Utrillas and Montalban at the West Lancashire Light Railway |

Thirdly, I have spent quite a bit of the summer, doing running repairs, constructing signals, making a set of buildings for the copper mine and experimenting with radio control (see below).

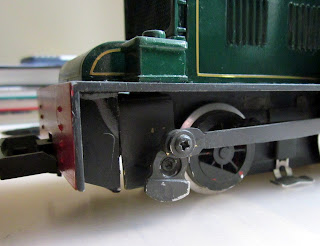

Running repairs

These have mostly centred on improving the running of stock which had wheels which were incompatible with LGB pointwork (see How I made IP Engineering wheels compatible with LGB pointwork). There would appear to be very little conformity over back-to-back measurements and flange depth of wheels across manufacturers when it comes to 45mm gauge. As a consequence, when products from different suppliers are brought together, there are often problems with smooth running through pointwork. Whilst I have sometimes re-wheeled stock to overcome these difficulties, there are occasions when this is not possible or desirable as, for example, when journals or axle stubs wheel sizes are non-standard. I have developed a rough-and-ready method of beefing-up finer scale wheels to improve their running characteristics through the coarser scale frogs of LGB pointwork.Another issue associated with LGB pointwork which I have uncovered over the seven years I've been running my railway has been a steady and consistent breakdown in electrical continuity between the running rails, point-blades and lead-rails before and after the frogs. I could have removed every point and soldered invisible connections beneath the rails and sleepers, but when I have done this in the past it has caused more problems than it solved. Consequently, I opted for an in-situ solution of soldering jumper wires from the stock rails to the switch rails.

For more information see - How I repaired LGB pointwork

Constructing signals

As I try to run my railway according to light railway prototypical practices (which of course were often quite idiosyncratic), I decided that with up to three trains in steam at any one time, it was about time I supplied the line with signalling.Using the signalling diagrams which were provided by a fellow modeller who also happens to be a Railtrack signalman (see Progress Report 36) ........

......... I figured that even the most minimal approach to signalling the railway would require 20 signals (around 4 per station). I explored various kit-built options but decided that the cost would be prohibitive. I had no option but to construct my own signals.

Although the signals were of the same basic design as I wanted to batch-produce them, there were two alternatives in terms of the types of base. One type had a plate base for mounting on hard surfaces, while the other had a concrete base, for mounting in soft surfaces .......

All the signals are equipped with flickering LED lamps..........

....... which are shuttered at the rear.

At present, the signals are operated individually but eventually I hope to have them operated through linkages to a ground frame at each station, as per prototype.

For details of construction see Garden Rail edition 224 (April 2013).

Mine buildings

Up until now, the sidings for the copper mine have had only a backdrop of the laurel hedge.Ever since the extension to Beeston Market and the copper mine was constructed (see How I built the extension), I have been planning to add some buildings and loading hoppers.

At this stage, construction is well under way - with a variety of techniques being deployed.

|

| The crusher shed and manager's office |

|

| The workshop |

The buildings are still very much work-in-progress with a lot more tidying-up and detailing needed. Once completed, the buildings will include a Gn15 feeder line from the mine workings together with loading hoppers and conveyors. See How I constructed the Mine Buildings)

Radio control

I have been broadening my experiments with battery operation and radio control, following the construction of my first battery powered radio controlled vehicle, a double-ended railbus (see How I constructed a railbus from two Andel coach kits).A chance-find on eBay resulted in the purchase of a couple of cheap 2.4GHz radio transmitters designed to be used with low-cost helicopters.

I discovered that the transmitters worked with cheap FlySky receivers and so, after setting-up a test-rig, I explored the potential of this cost-effective approach to radio control.

As you can see from the video, with the modest outlay I'm figuring it's worth producing a small fleet of battery-operated locos to run alongside and maybe eventually replace the track powered locos. I have a couple of spare ToyTrain loco blocks which can be pressed into service and one day I will get around to converting my LGB 0-6-2 U-Class Zillertalbahn loco into a representation of the Southwold Railway loco No. 4 Wenhaston.