Normally, I don't post that many Progress Reports in the winter months, but a few things have happened since my last report in January which are worth recording.

I still have to complete the interiors and add lighting. I'll probably add some cosmetic chopper couplings as well.

They took longer to convert than I had expected, but that was mainly because I decided to add a few more details than were absolutely necessary. I've described the conversion in another posting - see How I converted Bachmann Jackson Sharp coaches into Leek & Manifold coaches.

I tried to ensure that the running gear was not touched in any way as I knew these coaches would cope happily with the tight curves of my railway, however, I did extend the balconies by 10mm at each end. It was fortunate that I did not extend them further (to more closely match the capacious L&M originals) as on a couple of curves, the corners of the roofs touch each other. Had they been even a few millimetres longer they may well have levered each other off the track. You can just about see how close the coach roofs are in the fourth shot on this video of their test run.

It was powered by two AA Alkaline batteries and control was manual, through a reversing switch (no speed control).

I decided to upgrade it by using a 18650 rechargeable li-ion battery and adding radio control, using a Deltang Rx65b receiver/controller (see How I converted a battery diesel loco to radio control).

I also exploited one of the Rx65b's addition features, by re-programming the receiver to operate in auto-shuttle mode (see How I re-programmed a Deltang Rx65b for auto-shuttle mode).

I intend to use this loco to run a short train of skips from the copper mine to the loading hoppers and being able to leave it working in shuttle mode while I concentrate on operating the main railway. It will also be useful to have some 32mm gauge rolling stock to take on visits to fellow modellers' railways.

She will be re-painted and have more detailing added, numbered 11 and named Linda. The li-ion battery will be disguised as a fuel tank.

The main reason these have not been converted so far has been the availability of space for batteries. I do not like the idea of using a trail car for batteries as I often run trains end-to-end and, unless I provide them with tenders, I would not want to trail a wagon when running round the train. I am also taking the opportunity to replace some of the early Deltang receiver/controllers with the most recent Rx65b which has a higher power rating than its predecessors.

I am presently constructing a 32mm gauge Simplex loco kit (see Progress Report 56). I am hoping this can also be made to operate under radio control and in auto-shuttle mode as with Linda, above. This loco will be numbered 12 and named Emma.

At the start of each operating session, I will now run the rolling stock out to position wagons in their previous locations. I have created some namecards to act as dividers showing the origins of each rake.

The cosmetic Gn15 railway which previously served the loading hoppers

is being replaced with 32mm gauge track which will run a short distance beside the main line between the coper mine and Beeston Market Station. Work has started on making the embankment and bridges needed to take the railway to the loading hoppers.

I was also interested in finding out the haulage capabilities of another of my battery converted locos (Barclay 2-4-0 loco No.2 Beeston).

This winter has been very mild in comparison with previous winters, and I have been able to keep the trains running more frequently. I must admit that converting to battery power has been one of the main reasons for encouraging me to grab opportunities to run trains with the minimum of preparation.

Leek & Manifold coaches

I am pleased to report that the Leek & Manifold (ish) coaches which I bashed from Bachmann Jackson Sharp (ish) coaches are now completed - well externally.I still have to complete the interiors and add lighting. I'll probably add some cosmetic chopper couplings as well.

They took longer to convert than I had expected, but that was mainly because I decided to add a few more details than were absolutely necessary. I've described the conversion in another posting - see How I converted Bachmann Jackson Sharp coaches into Leek & Manifold coaches.

I tried to ensure that the running gear was not touched in any way as I knew these coaches would cope happily with the tight curves of my railway, however, I did extend the balconies by 10mm at each end. It was fortunate that I did not extend them further (to more closely match the capacious L&M originals) as on a couple of curves, the corners of the roofs touch each other. Had they been even a few millimetres longer they may well have levered each other off the track. You can just about see how close the coach roofs are in the fourth shot on this video of their test run.

New loco (and new gauge)

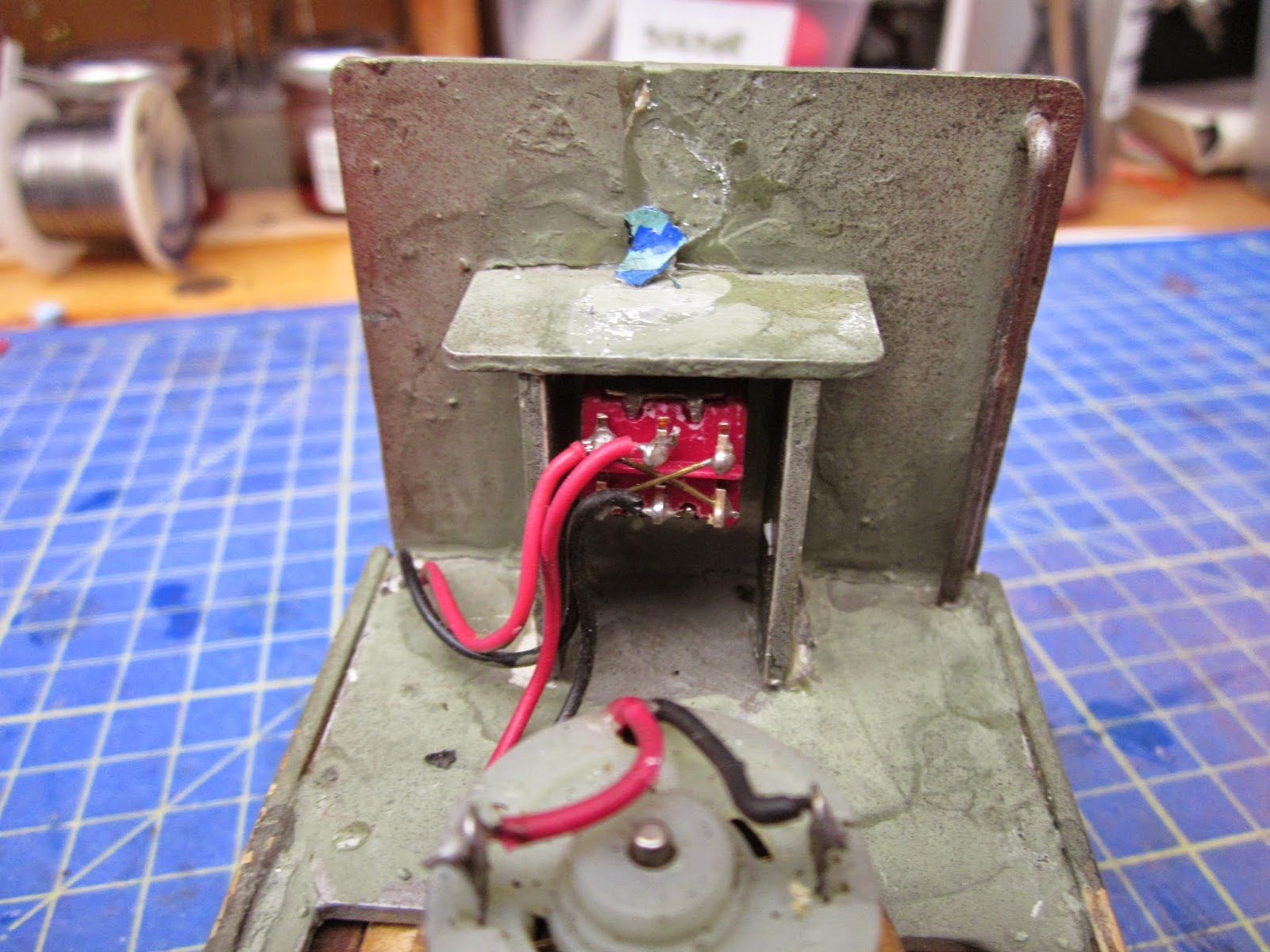

I don't always manage to find bargains on eBay, but a couple of weeks ago, I stumbled across a nice little 32mm gauge IP Engineering diesel loco which was going for a very reasonable Buy It Now price.It was powered by two AA Alkaline batteries and control was manual, through a reversing switch (no speed control).

I decided to upgrade it by using a 18650 rechargeable li-ion battery and adding radio control, using a Deltang Rx65b receiver/controller (see How I converted a battery diesel loco to radio control).

I also exploited one of the Rx65b's addition features, by re-programming the receiver to operate in auto-shuttle mode (see How I re-programmed a Deltang Rx65b for auto-shuttle mode).

I intend to use this loco to run a short train of skips from the copper mine to the loading hoppers and being able to leave it working in shuttle mode while I concentrate on operating the main railway. It will also be useful to have some 32mm gauge rolling stock to take on visits to fellow modellers' railways.

She will be re-painted and have more detailing added, numbered 11 and named Linda. The li-ion battery will be disguised as a fuel tank.

Loco repairs and upgrades

As with the real thing, my model locos usually require some TLC to keep them in operating condition and over the winter period I tend to do general maintenance and servicing. I am intending to convert my remaining three track-powered locos to battery power.The main reason these have not been converted so far has been the availability of space for batteries. I do not like the idea of using a trail car for batteries as I often run trains end-to-end and, unless I provide them with tenders, I would not want to trail a wagon when running round the train. I am also taking the opportunity to replace some of the early Deltang receiver/controllers with the most recent Rx65b which has a higher power rating than its predecessors.

I am presently constructing a 32mm gauge Simplex loco kit (see Progress Report 56). I am hoping this can also be made to operate under radio control and in auto-shuttle mode as with Linda, above. This loco will be numbered 12 and named Emma.

Stock storage

Owing to a chronic medical problem, I have had to abandon use of stock boxes to transport and store my rolling stock - instead, I have created storage tracks in the garage and have extended the baseboard at Beeston Market (see How I made some storage roads in the garage)At the start of each operating session, I will now run the rolling stock out to position wagons in their previous locations. I have created some namecards to act as dividers showing the origins of each rake.

Peckforton Mine Tramway (PMT)

As indicated above, I have decided to create a 32mm (2') gauge railway to act as a feeder for the main 3' gauge railway. I have already acquired and modified one loco and am in the process of constructing a second (see above.The cosmetic Gn15 railway which previously served the loading hoppers

is being replaced with 32mm gauge track which will run a short distance beside the main line between the coper mine and Beeston Market Station. Work has started on making the embankment and bridges needed to take the railway to the loading hoppers.

Winter running

During the winter, I don't usually run full operating sessions, preferring to make the most of breaks in the weather to run the odd train now and again. I did, however, make the most of a light snow shower to run a couple of trains in the snow.I was also interested in finding out the haulage capabilities of another of my battery converted locos (Barclay 2-4-0 loco No.2 Beeston).

This winter has been very mild in comparison with previous winters, and I have been able to keep the trains running more frequently. I must admit that converting to battery power has been one of the main reasons for encouraging me to grab opportunities to run trains with the minimum of preparation.