This kit has been sitting in one of my project boxes for at least five years and so I felt it was about time I constructed it. When I bought the kit, it came without wheels which

suited me as I have found that the steel wheels which come with IP Engineering kits are not always compatible with my LGB pointwork - I have found the flanges are too fine and have a tendency to ride-up on the point blades or sometimes the back to back distance is too great and the wheels refuse to be guided by the check rails and foul the frog. Maybe things have changed since I created this post on modifying IP Engineering wheels to help improve their compatibility with LGB pointwork way back in 2012. By contrast, I believe there are no compatibility issues with IP Engineering wheels and Peco pointwork.

This kit has been sitting in one of my project boxes for at least five years and so I felt it was about time I constructed it. When I bought the kit, it came without wheels which

suited me as I have found that the steel wheels which come with IP Engineering kits are not always compatible with my LGB pointwork - I have found the flanges are too fine and have a tendency to ride-up on the point blades or sometimes the back to back distance is too great and the wheels refuse to be guided by the check rails and foul the frog. Maybe things have changed since I created this post on modifying IP Engineering wheels to help improve their compatibility with LGB pointwork way back in 2012. By contrast, I believe there are no compatibility issues with IP Engineering wheels and Peco pointwork.So, the kit was unpacked ......

... and the comprehensive instructions consulted.

These kits are very straightforward to construct and so would suit a novice garden railway modeller. They also represent good value for money at £35 for the kit (at time of writing), including the wheels.

After carefully removing the parts from the sheets, using a sharp craft knife, they were tidied-up with a sanding block. The ends and their overlay frameworks were identified ....

..... and the frames glued to the ends. I used thick superglue as I am somewhat impatient and prefer a faster setting-time than is achievable with PVA based wood glues.

The frameworks for the sides were located ......

...... as were the sides .......

..... and the frames glued on.

One end was then glued to one side.......

..... using a tri-square to help ensure the joint was square.

The assembled end/side was then glued to the base.

The same process was followed for the remaining end and side .......

So far, the construction had taken less than half an hour and already the wagon was taking shape.

I then turned my attention to the axle boxes and hangers. The brass bushes were inserted into the hangers ......

...... and glue applied to the rear of the solebars and springs.

The hangers were then glued on.

This was repeated until all four axle boxes had been assembled.

The headstocks were then glued to the base of the wagon and the solebars trimmed to fit. Only a few millimetres needed to be removed from each end. I decided to use Bachmann 24.5mm diameter wheels as I know these are compatible with my pointwork. The ends of the axles were inserted into the bearings and the solebars positioned until they were central. I then applied a generous fillet of thick superglue to the upper edges and ends of the solebars and then squirted some superglue activator on to the joints to provide an almost instantaneous bond. This saves having to clamp or hold the solebars in position while the glue sets.

NOTE: The advantage of using the Activator spray is the immediacy with which the bond is achieved. The disadvantage is that once the spray is applied, there is no opportunity for fine adjustment, so I had to be certain the solebars were correctly positioned before using the spray.

I then attached the central buffers. Because the buffers on my other rolling stock are higher than the default position on the IP wagon, I had to glue on a small piece of thin plywood (cut from the fret) and drill a new 3mm hole for the bolt on the rear of the buffer.

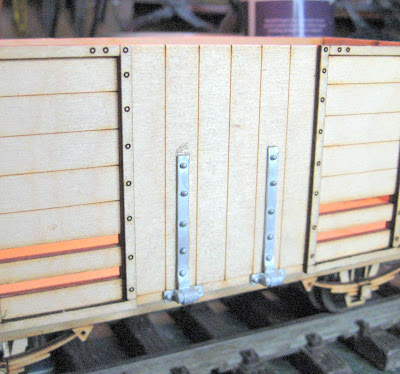

Although the instructions suggest that the hinges should be glued on after the body has been painted, I decided to glue them on at this stage. I am happy to paint them in situ (see below).

The next stage was to take the wagon to the paint shop. I applied masking tape to the wheels and axles and then gave the wagon body a couple of coats of Halford's grey primer from a rattle can aerosol. This was left for a couple of days to harden off.

As can be seen, the finish is quite rough and so, I then used some fine emery paper to smooth off the paintwork. I used 600 grade wet and dry wrapped around a small block of balsa to help get a smooth finish.

There were some gaps at the corners where the ends and the sides had not fitted as snugly as I would have hoped and so the gaps were filled with Squadron White Putty filler which I buy from Eileen's Emporium. The putty only takes around 20 minutes to harden after which it was rubbed down with a sanding block and 600 grade wet and dry.

I decided, at this stage, to 'distress' the wagon slightly and so attacked the ends of the vertical boards of the doors with a craft knife to give the appearance of wear and tear.

I also scored the lines between the planks more deeply and attacked some of the gaps with a craft knife to give the impression that some boards were beginning to show their age.

A scriber point was also dragged lightly across the surfaces of the 'planks' in the direction of the grain to give it a slightly aged look.

I decided to add rivet heads to the 'ironwork' instead of relying on the laser-cut circles which had been used to represent them. Small blobs of thick superglue were applied to the position of each rivet head with the point of a cocktail stick.

2mm diameter half-round nail art pearls were then picked-up with the same cocktail stick, the residue of glue being sufficient to attract the pearl. The pearls were then transferred to the blobs of glue on the model.

NOTE: Nail art pearls )or gems) can be purchased from a well known online auction site. I got a pack of 1000 for 99p (including postage). It's also possible to buy hexagonal pearls to represent bolt heads

Once all the rivet heads had been glued to the bodywork ......

.... a 3mm half round nail pearl was glued to the end of each axle box and 2mm pearls were glued to the spring pivots.

I then gave the whole model another couple of coats of grey primer.

Once the primer had hardened-off (a couple of days), I hand-painted the metal frames, hinges, solebars, axle boxes, springs, headstocks and buffers with black acrylic paint.

This can be quite time-consuming but I usually try to coincide jobs like this when there's a decent afternoon play on Radio 4 and so the time passes quite quickly.

After gauging the correct height for the couplings (by lining it up with another wagon on a piece of track), I glued and screwed wooden mounting blocks at each end of the chassis.

The headstocks were slotted to take the fronts of the couplings .........

..... and then the couplings were screwed to the blocks.

The wagon was then allowed to enter service.

Once the paintwork has hardened off, I will apply some light weathering to emphasise the planking and to suggest the wagon has been in service for some time.

I then decided to give the wagon some light weathering using my tried and trusted techniques (see How I weather my wagons).

I also added a couple of simple latches to each of the drop-down doors made from some offcuts of plasticard, plastic tube and brass rod.

Some sheep from DesignPrintScan3D were painted to resemble Oxford Down sheep

Some 'straw' was added to the wagon floor, kindly donated by a yard broom.

And then the sheep were glued into place.

Whilst the wagon was in the paint-shop, I also re-liveried and weathered my most recent Llanfair GR Show bargain-find (a Tralee and Dingle cattle truck).

They should add a bit of variety in mixed goods trains and so I am looking forward to having some decent weather when I can give them both a good airing.

I would like to build a couple of Welshpool and Llanfair style sheep wagons to complement these two wagons and have already worked out how they might be adapted to fit on to Hartland Loco Works (HLW) chassis, my default donor for many of my wagon scratch-bash builds. As they say, watch this space!

No comments:

Post a Comment