A brief history of Bickerton Copper Mine

It is thought that copper has been mined at Bickerton and Gallantry Bank since the Bronze Age and by the Romans, but the earliest

documented reference to mining in the area is in a report written by J D

Brandshagen in 1697 for Sir Philip Egerton. The sandstone outcrop at Peckforton forms part of the same geology as that of Alderley Edge, where there is also evidence of copper mining (See

Copper Mining at Alderley Edge).

|

| Alderley Edge Copper Mine: Source http://www.derbyscc.org.uk/caving/caving_image/JK_trip_20060507_21_resize.jpg |

The seams of copper were worked intermittently until the 1860s though there was an optimistic survey carried out in 1906 in a bid to raise capital for a more extensive mining venture.

Today, there is very little evidence of the copper mining industry at Bickerton and Peckforton. It is possible to squirm into an abandoned adit in the hillside above the

Bickerton Poacher pub, but the five main shafts to the deeper copper seam have long since been sealed. The remains of the chimney for the boiler serving the pumping engine above the main Engine Shaft can be seen from the A534 road.

|

| The remains of the chimney beside the sealed Engine Shaft (Source: http://upload.wikimedia.org/wikipedia/commons/7/70/Copper_mine_chimney_-_geograph.org.uk_-_713124.jpg) |

I have been unable to find any drawings or photos of the copper mine when it was operational, the earliest I've been able to discover shows it in a derelict state taken at the beginning of the 20th century:

|

| Bickerton Cooper Mine circa 1904 (Source: http://www.sandstonetrail.com/wp-content/uploads/Coppermine.jpg) |

The mines

Although

Shaft No. 5 and the Pit were shown in an 1890 survey of the mine workings (Edwards, 1890), only the Engine Shaft and Shafts 1, 2, 3 and 4 are shown in the 1906 survey (Spargo & Thomas, 1906) suggesting these were the only workable shafts at that time. This drawing shows the approximate position and extent of the workings based on these two surveys (click on the image to enlarge).

|

| Bickerton Copper Mine (Based on Carlon (1981) Fig vii) |

The Engine Shaft was the deepest, at 156 feet, No. 1 shaft was around 60 feet deep, No. 2 shaft was 35 feet deep, No. 3 shaft was around 110-120 feet deep, shaft No. 4 was somewhere between 117 and 135 deep while shaft no. 5 was 65-70 feet deep. As the the ore zone was inclined at an angle of approximately 80 degrees to the vertical, various levels and stopes needed to be worked from the shafts to access the ore. Shafts No. 4 and 5 were the oldest, and were worked until the beginning of the 19th century. Only Shaft 3 continued working after the mid 1800s. The pit between shafts 4 and 5 was later used as a well.

It is assumed that the mine shafts at Bickerton were relatively dry as the pumping engine over the Engine Shaft was a modest affair. Over the years, advice had been sought from Cornish mining engineers and so it is highly likely that the mining practices at Bickerton would have been heavily influenced by those carried out in Cornwall.

|

| The type of pumping engine house possibly used at Bickerton (Source: http://farm5.static.flickr.com/4079/4798065476_e74ec2c1ee.jpg) |

As the main shaft used for the extraction of ore was Shaft No.3 it must be assumed there was some sort of winding engine situated nearby, though this is not documented in any of the sources consulted.

|

| Steam powered winding engine used in copper mine (Source http://s0.geograph.org.uk/geophotos/02/32/38/2323827_775bb0fa.jpg) |

Through the 18th and 19th centuries various schemes were put into effect to develop the mine but by th

e turn of the 19th century, the mine had been left unworked for around 35 years. Edmund Spargo's survey of 1906 concluded that by widening and deepening the main shafts the mine could easily be expected to yield around 18000 tons of copper which would net a profit of around £1.1m (equivalent to around £115m today)! The Bickerton Copper Mines Syndicate Ltd. leased the mines for three years in 1907 but seem to have carried out very little work and was dissolved in 1911. In 1917, UK Minerals Development took out a three year lease of the mine but again very little work took place. During the 1920s, three local men worked No. 3 shaft intermittently using a bucket, rope and hand winch and unearthed some rich pieces of bright blue crystalline azurite.

|

| Azurite and malachite (Source: http://upload.wikimedia.org/wikipedia/commons/9/97/Azurite-Malachite-59275.jpg) |

By the 1930s the mines gradually fell into decay until the shafts were filled and sealed in the 1960s and what remained of the mine buildings were demolished in a road widening scheme in 1977.

The minerals

There were two veins of copper-bearing rock in the mine at Bickerton which varied in width from eight inches to five feet, with an average of 2½ feet. There was also thought to be cobalt, lead and silver deposits in the seams. In 1802 a sample of ore from Bickerton was sent to the Mineralogical Society for analysis which pronounced there was 9% copper in the sample in the form of copper sulphide and copper carbonate. However, another analysis in 1806 found the ore varied in quality from 0% to 2½%, whereas another in 1862 found there was between 19¼% and 25% of copper and 18 ounces of silver per ton of ore.

The minerals present in the ore were malachite and principally azurite, though there were also traces of chrysocolla, melaconite, bornite and covellite. These were deposited in an almost vertical fissure of white sandstone, similar to that found at Alderley Edge, Clive, Pim Hill, Whixall and Eardiston.

|

| Mineralised sandstone from Alderley Edge (Source: Minerals UK) |

The copper mining process

Until the middle of the 19th century, copper was extracted and processed mainly by hand, but thereafter mechanisation played an increasing role. By the early 1930s, when my model is set, pneumatic and hydraulic mining equipment would have been used, though this would also have been supplemented by hand tools and the use of explosives. As the shafts and galleries were very narrow, it seems reasonable that the narrowest gauge of railway would have been used to transport the ore and spoil beneath the ground. Railway tracks were found in the mines at Alderley Edge - though these are associated with later restoration work.

|

| Copper Mines at Alderley Edge (Source: http://www.mine-explorer.co.uk/photo_cache/mines/Alderley-edge_2547/Alderley-edge_22468.jpg) |

By contrast, in the Parys Mine in Anglesey there were no underground railways in the

copper mine owing to the corrosive effects of contaminated water on the

equipment (see

Parys Underground Group - Railways). As we have seen above, the mines at Alderley Edge and Bickerton were relatively dry and it is more likely they would have used underground railway trucks to transport the ore and spoil if the mines had been further developed.

|

| Tub from the Saint Veran Copper Mine in France (Source http://www.aditnow.co.uk/photo/Personal-Album-1-Image-067) |

Once extracted from the mine the ore was crushed and then ground before the copper-bearing minerals were further extracted using an oil flotation process where the impurities rose to the surface and were skimmed off. The ore would then be smelted and refined.

|

| Copper Processing (Source: www.bgs.ac.uk/downloads/start.cfm?id=1410) |

Once the ore had been removed from the mine and crushed, any rock which held more than 5% of

copper could be sent directly to the smelters while any below that could

be treated using the wet acid process which would produce copper

sulphate (used as a crop spray).

The (fictional) history of the Peckforton Light Railway

To provide my 16mm scale garden railway with a realistic context, I have made some hypothetical propositions and just a few flights of fancy. However, where possible, these have been based on facts and reflect what might have happened, given the certain favourable conditions.

My fictional inventions are shown in italics, the rest is factual.

In my imagined history (see

A History of the Railway),

the local landowner, Lord Tollemache,

decided to invest in the copper

mines following the optimistic report produced in 1906 by Spargo and Thomas.

As a consequence built a three foot gauge railway to transport the mined ore

and spoil to the mainline Crewe to Chester railway via the former Beeston & Tarporley Station. Bentley Tollemache succeeded his father,

Wilbraham, as the 3rd Baron Tollemache in 1904 and as such became the

owner of the Peckforton Estate which included Peckforton Castle.

Peckforton Castle was built in the middle of the nineteenth century by

his grandfather, John Tollemache (see

History of Peckforton Castle). It was designed in the Gothic style by

the architect

Anthony Salvin and was described in

1858 by Sir George Gilbert Scott, the architect of St Pancras Station,

as "the

largest and most carefully and learnedly executed Gothic mansion of the

present."

|

| Peckforton Castle shortly after completion in 1851 (Source: http://www.dicamillocompanion.com/images/Houses/database/Peckforton_Castle.jpg) |

Bentley Tollemache was actually a keen amateur engineer and I

like to imagine that, as a consequence,

he would have been very

enthusiastic about constructing a narrow gauge railway to

serve his pet project, the mining of copper on the edge of his estate. I

also hypothesise that he would have constructed a 15" minimum gauge

railway to handle freight within his estate, inspired by that

constructed by his near neighbour, the Duke of Westminster at Eaton Hall

(see

Eaton Railway)

and influenced by the work of Sir Arthur Heywood (see

Historical Background to Minimum Gauge Railways)

|

| Source: http://www.eatonestate.co.uk/NR/rdonlyres/914E2056-B26C-4216-9DD2-3E2E28C8E274/8142/Katie.jpg |

I am assuming that as the ores were relatively copper-rich at Bickerton

(if Spargo & Thomas are to be believed),

once extracted from the

mine they would then crushed before being loaded into wagons for

transhipment to be processed and smelted elsewhere - maybe near the sister mines at Alderley Edge. I am also assuming

that Lord Tollemache was a canny businessman and that he would have

identified a ready market for the non-copper-bearing spoil. The sea

defences along the Dee Estuary were being reinforced during the period in which my model is set and hence there would have been a call for crushed

rock and rubble from a range of sources.

|

| The Dee Estuary (Source: http://www.gutenberg.org/files/29787/29787-h/images/p033.jpg) |

My model of the mine assumes that more than one shaft would have been enlarged to allow for the mechanical extraction of the copper ores. Furthermore, additional shafts will have been sunk along the ore line to gain access to other rich deposits of copper-bearing ores. These shafts would have been interlinked at the surface by a 15" minimum gauge railway using internal combustion powered locomotives. Rock from the workings would be transported to the crushing and sorting machinery housed in sheds adjacent to the pumping engine and old mine workings beside the Engine Shaft.

The pumping engine would have been updated, but remained steam driven, whereas the crushing, sorting and conveyor mechanisms would have been powered by diesel engines.

|

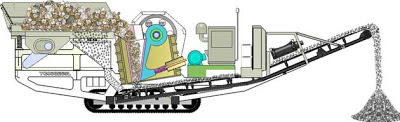

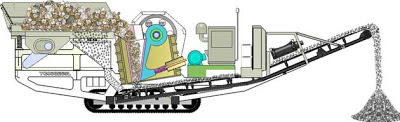

| Ore crusher (Source: http://www.bricscrushingplant.com/images/solutions/gen/36.jpg) |

Although the image above shows a modern mobile ore crusher, the technology has not changed radically over the years and a similar, albeit stationary, system of crushing would have been in use in the 1930s. The ore is loaded into a hopper on the left and is fed into the crusher mechanism, which crushes the ore between fixed and movable jaws. The crushed ore is then conveyed to a loading hopper

(see How I constructed a wooden loading hopper).

By 1932, when my model is set, I'm assuming that the viably workable seams were becoming exhausted and so there was proportionately more spoil being extracted than copper ore. As a consequence, there was less money available for carrying out repairs and the railway and the works were beginning to fall into decay. However, the tourist potential of the area was becoming more lucrative as the healing powers of the mineral waters in the Peckforton Hills were being exploited and the largely unspoilt scenery around Beeston and Peckforton Castles proved attractive for Bank Holiday visitors from Manchester and Birmingham.

Bibliography

- C.J. Carlon.

(1981) British Mining No.16:- The Gallantry Bank Copper Mine, Bickerton, Cheshire

- H. Dewey. T. Eastwood.

(1921) MGS Special Reports, Vol. XXX: Copper ores of the Midlands

6 comments:

Very informative article, i've been looking for information on this for ages.

Thanks!

In a lot of articles the reference " It is possible to squirm into an abandoned adit in the hillside above the Bickerton Poacher pub" has been used, however despite living in burwardsley and walking these hills every day with my dogs for most of my life, I have never found the adit. Does anyone have a better description other than "above the bickerton poacher" as this roughly covers about 4km Sq. Excellent article though.

I haven't checked it lately (there was talk of it being filled-in for H&S), but the adit is just below the path which goes up the hillside from opposite Bulkeley Mill. As the path reaches the top of the slope and turns right to head towards the Sandstone Trail, the adit is more or less directly below - about halfway between the path and the field boundary.

There is a hole next to the chimney now any info on that?

Hi Eric

It's the Engine Shaft (see plan). It seems to have deepened in the past few years. It used to be a small depression but the infill seems to have slipped so you can now see the brick lining.

Rik

Thank you for your reply very surprised no one has actually made it down yet

Post a Comment