This Blog describes the ongoing development of a 16mm scale 45mm gauge garden railway situated in the North West of England, UK from 2004 to the present day.

Wednesday, December 27, 2006

Friday, July 21, 2006

Progress Report 7 - The patio

Before the Grand Opening Ceremony, there were a few loose ends which needed tidying up - some related to the railway and others to do with the garden itself.

The patio-to-be becomes a very 'cosy' patio

Indian sandstone (cheaper than 'riven' concrete slabs) was laid to form the patio. As this was very much last-minute, the slabs were laid on a bed of dry-mix concrete (four parts sand to one part cement). I found the levelling of the slabs quite easy with this method as the slabs are of varying thicknesses. It also meant the could be walked on sooner than if I'd used a wet mix. I watered them in and so far (touch wood) none seems to have sunk.

The stream sump is beautified

Reading 'How I created the stream' you will see I used a plastic dustbin (£10.00) for the sump. Until recently it resembled nothing more than a plastic dustbin sunk into the ground with a rather prominent tube disappearing into the stream bed. After pricing purpose-made sumps, I decided to use my initiative. I drilled a series of holes in the plastic dustbin lid it, then placed it, inverted, on top of the dustbin. A couple of £5.00 bags of pebbles and, tra-lah - one rather elegant end to the stream. A purpose made sump of the same size would have cost £70+!

[Update - April 2009] Each spring I clean out the stream and unclog the pump. I was alarmed to find the decomposing bodies of three small frogs in the sump. Presumably, they had managed to squeeze in where the pipe comes out of the lid but were unable to climb back out again and so drowned. I decided therefore to modify the lid to provide an escape route for adventurous frogs.

With a piercing saw, I cut a flap in the lid of the dustbin which was then bent downwards to act as a platform for the froglets. Whenever I run the pump I now make sure I top up the sump to ensure the water level is up to the flap. I will check again next spring to see if my cunning scheme has worked.

With a piercing saw, I cut a flap in the lid of the dustbin which was then bent downwards to act as a platform for the froglets. Whenever I run the pump I now make sure I top up the sump to ensure the water level is up to the flap. I will check again next spring to see if my cunning scheme has worked.

[Update November 2017] - I am pleased to report that since making this hatch, I have not found another dead froglet in the sump.

The switch-back leading to the patio bridge is evened-out

As mentioned in the previous progress report, there was a nasty hump on the approach to the switch bridge leading to the patio. To iron this out, the three blocks leading to the bridge were lifted and relaid, and the concrete and stone abutment was chiselled out to a lower level. There is still a very slight hump but nowhere near as noticeable as before.

The patio-to-be becomes a very 'cosy' patio

Indian sandstone (cheaper than 'riven' concrete slabs) was laid to form the patio. As this was very much last-minute, the slabs were laid on a bed of dry-mix concrete (four parts sand to one part cement). I found the levelling of the slabs quite easy with this method as the slabs are of varying thicknesses. It also meant the could be walked on sooner than if I'd used a wet mix. I watered them in and so far (touch wood) none seems to have sunk.

The stream sump is beautified

Reading 'How I created the stream' you will see I used a plastic dustbin (£10.00) for the sump. Until recently it resembled nothing more than a plastic dustbin sunk into the ground with a rather prominent tube disappearing into the stream bed. After pricing purpose-made sumps, I decided to use my initiative. I drilled a series of holes in the plastic dustbin lid it, then placed it, inverted, on top of the dustbin. A couple of £5.00 bags of pebbles and, tra-lah - one rather elegant end to the stream. A purpose made sump of the same size would have cost £70+!

[Update - April 2009] Each spring I clean out the stream and unclog the pump. I was alarmed to find the decomposing bodies of three small frogs in the sump. Presumably, they had managed to squeeze in where the pipe comes out of the lid but were unable to climb back out again and so drowned. I decided therefore to modify the lid to provide an escape route for adventurous frogs.

With a piercing saw, I cut a flap in the lid of the dustbin which was then bent downwards to act as a platform for the froglets. Whenever I run the pump I now make sure I top up the sump to ensure the water level is up to the flap. I will check again next spring to see if my cunning scheme has worked.

With a piercing saw, I cut a flap in the lid of the dustbin which was then bent downwards to act as a platform for the froglets. Whenever I run the pump I now make sure I top up the sump to ensure the water level is up to the flap. I will check again next spring to see if my cunning scheme has worked.[Update November 2017] - I am pleased to report that since making this hatch, I have not found another dead froglet in the sump.

The switch-back leading to the patio bridge is evened-out

As mentioned in the previous progress report, there was a nasty hump on the approach to the switch bridge leading to the patio. To iron this out, the three blocks leading to the bridge were lifted and relaid, and the concrete and stone abutment was chiselled out to a lower level. There is still a very slight hump but nowhere near as noticeable as before.

A decent track cleaning rubber has been bought

Relatively expensive at £20 from GRS (Garden Railway Specialists), but as track cleaning is now down to around 30 minutes as opposed to the 2 hours or more it took previously, I consider this well worth the investment!!

<< Go to Progress Report 6

Relatively expensive at £20 from GRS (Garden Railway Specialists), but as track cleaning is now down to around 30 minutes as opposed to the 2 hours or more it took previously, I consider this well worth the investment!!

<< Go to Progress Report 6

Sunday, June 18, 2006

How did I make the control panel

I decided from the start I would keep the control panel as simple as possible. I considered arranging the switches on a layout diagram but, as at some point in the future, I will probably extend the line, it seemed more sensible to have a bank of switches which could be re-assigned as needs arise.

Materials

A trip to my local electronics store (Maplin) provided me with the following:

1 x ABS project box (191mm x 110mm x 57mm) @ £3.79

5 x ON-OFF-ON DPDT subminiature toggle switches @ £1.94 ea

1 x ON-ON DPDT subminiature toggle switch @ £1.96

9 x (ON)-OFF-(ON) DPDT subminiature toggle switches @ £1.94 ea

Section switches

The ON-OFF-ON switches were wired up to control the sections. Flicking the switch to the right enables the right hand controller to power the section and vice versa. The ON-ON switch has been wired into the circuit for the reversing loop (track section A) to enable the polarity to be switched independently of the rest of the layout, thereby enabling reverse running over this section without short circuit.

NOTE: ON-OFF-ON switches can be switched to one of three positions left, right or centre (off)(upright).

Points switches

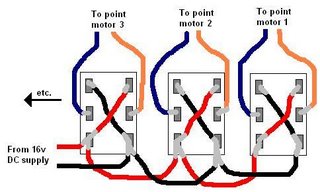

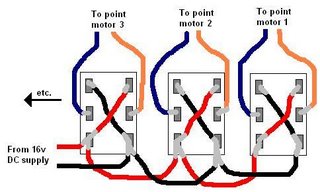

The (ON)-OFF-(ON) points switches were wired up us reversing switches, with a 16v DC transformer (purchased for £1.00 from a swapmeet), providing the power source:

NOTE: (ON)-OFF-(ON) means that the switch biased to remain in the centre 'off' position. After switching either way it springs back to the centre off position. This makes it ideal for point switching as the point motor needs only a momentary pulse of electricity to operate.

Finishing off

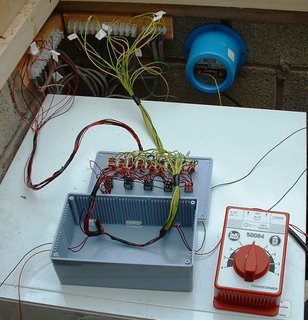

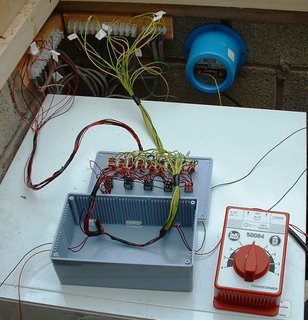

Although the the result looks like a knitting basket, it does the job:

As can be seen from the above photo, the wires from the control panel are connected to the heavier weight wiring used in the garden via connection blocks. These are hidden beneath the work-surface to provide a reasonably tidy finish.

The control box has been tested and functions well. The finishing touch will be the addition of a second transformer/controller. These seem to come up on eBay regularly for quite reasonable prices. Though, as indicated above, until I have at least one more loco, a second controller is not needed.

Materials

A trip to my local electronics store (Maplin) provided me with the following:

1 x ABS project box (191mm x 110mm x 57mm) @ £3.79

5 x ON-OFF-ON DPDT subminiature toggle switches @ £1.94 ea

1 x ON-ON DPDT subminiature toggle switch @ £1.96

9 x (ON)-OFF-(ON) DPDT subminiature toggle switches @ £1.94 ea

Section switches

The ON-OFF-ON switches were wired up to control the sections. Flicking the switch to the right enables the right hand controller to power the section and vice versa. The ON-ON switch has been wired into the circuit for the reversing loop (track section A) to enable the polarity to be switched independently of the rest of the layout, thereby enabling reverse running over this section without short circuit.

NOTE: ON-OFF-ON switches can be switched to one of three positions left, right or centre (off)(upright).

Points switches

The (ON)-OFF-(ON) points switches were wired up us reversing switches, with a 16v DC transformer (purchased for £1.00 from a swapmeet), providing the power source:

NOTE: (ON)-OFF-(ON) means that the switch biased to remain in the centre 'off' position. After switching either way it springs back to the centre off position. This makes it ideal for point switching as the point motor needs only a momentary pulse of electricity to operate.

Finishing off

Although the the result looks like a knitting basket, it does the job:

As can be seen from the above photo, the wires from the control panel are connected to the heavier weight wiring used in the garden via connection blocks. These are hidden beneath the work-surface to provide a reasonably tidy finish.

The control box has been tested and functions well. The finishing touch will be the addition of a second transformer/controller. These seem to come up on eBay regularly for quite reasonable prices. Though, as indicated above, until I have at least one more loco, a second controller is not needed.

Tuesday, June 13, 2006

Progress Report 6 - Electrics

A week of almost unbroken sunshine has meant a lot of time spent in the garden. However, work commitments have provided precious little time to do anything other than titivate. However, I have managed a few further developments:

- The sump for the stream has been enlarged - a plastic dustbin providing a cheap and effective solution

- Mains electrics have been laid outside (suitably protected with an RCD - see above)

- Low voltage lighting has been added around the patio-to-be

The control panel / switch box, is under construction.

The top row of switches are to energise the various electrical sections around the line, the middle row of switches operate the point motors on the pointwork and the solitary switch on the bottom right reverses the polarity on the reverse loop.

The most pressing job at the moment is to find a way of eliminating a hump at the end of the swing bridge, which will entail raising the breeze block on to which the track is fixed.

Things are moving on. The railway is taking shape.

<< Go to Progress Report 5

Monday, May 29, 2006

How did I Bond the Rails?

I decided from the outset that all rail joints would be bonded. Rather than relying on the fishplates / rail-joiners to make electrical contact, I opted to solder links across the rail joints. This would not have been possible without the 75 watt soldering iron which I purchased some years ago.

Firstly, the tools needed for the job are gathered - soldering iron (75 watt), multi-core solder, pointed nose pliers, wire cutter, small screwdriver, 1mm copper wire.

I then, clean the area to be soldered by filing or scraping down to bare metal:

Next, heat is applied to the rail and the solder is melted on to soldering iron which, when it is hot enough, runs on to the rail:

The copper wire is cut to length, with a loop included for expansion. The ends of the wire are tinned with solder:

Finally, the wire is soldered to the rail, by applying heat from the iron until the solder on the wire and the rail melt together.

The composition of the brass for Aristocraft rail seems different to the LGB rail. Aristocraft rail does not become tarnished so readily but is more difficult to solder; it seems to dissipate the heat more quickly and hence the solder does not bond quite so well.

Firstly, the tools needed for the job are gathered - soldering iron (75 watt), multi-core solder, pointed nose pliers, wire cutter, small screwdriver, 1mm copper wire.

I then, clean the area to be soldered by filing or scraping down to bare metal:

Next, heat is applied to the rail and the solder is melted on to soldering iron which, when it is hot enough, runs on to the rail:

The copper wire is cut to length, with a loop included for expansion. The ends of the wire are tinned with solder:

Finally, the wire is soldered to the rail, by applying heat from the iron until the solder on the wire and the rail melt together.

The composition of the brass for Aristocraft rail seems different to the LGB rail. Aristocraft rail does not become tarnished so readily but is more difficult to solder; it seems to dissipate the heat more quickly and hence the solder does not bond quite so well.

Progress Report 5 - Ballasting

This (Bank Holiday) weekend has seen completion of a number of unfinished jobs:

The siding in the main station has been laid

All rail joints have now been bonded

All visible track has been ballasted (the cement method - see How I ballasted my track)

A trip to Bay Models in Carnforth saw the purchase of the final point needed to complete the tracklaying in the storage yard, and the impulse buy of an Accucraft covered van (based on the Welshpool and Llanfair). Ultimately, the LGB stock from the starter set will be Anglicised - loosely based on the W&L.

Before the sidings in the storage yard are laid, I am trying to find a way of incorporating a microswitch into the point motor housing. LGB points are non-isolating, which means that all sidings will be live regardless of the way the points are set. The points could be converted to isolating by rewiring, but this would then rely on the blade making good contact - a potential headache for an outdoor line. The cost of over £15.00 (gbp) for the LGB accessory switch for their point motors seems excessive, particularly as the Aristocraft point motors include these as standard. Fortunately, the modification needed to incorporate a microswitch seems relatively straightforward. More details to follow.

(By the way, the blue plastic sheeting which can be seen in the photos is to protect the newly ballasted track from the rain. This is to avoid the cement from being washed out)

<< Go to Progress Report 4

Sunday, May 07, 2006

Progress Report 4 - Snagging

Barbecue

Friday was a gorgeous day - unbroken sunshine and, for almost the first time this year, pleasantly warm. An impromptu barbecue was organised after work. Very pleasant to sit in the garden with a glass of fizz and blackened meat which was once a kebab, with a train chugging away in the background.

Snagging

The weekend was spent mostly in sorting out some of the snags from tracklaying so far. I decided that, rather than lifting track and levelling the underlying trackbed, I would try a less radical solution. I figured that even after re-laying the blocks, they could re-settle and then I'd have to re-do the whole procedure. Besides, I wanted an easier life!

snags from tracklaying so far. I decided that, rather than lifting track and levelling the underlying trackbed, I would try a less radical solution. I figured that even after re-laying the blocks, they could re-settle and then I'd have to re-do the whole procedure. Besides, I wanted an easier life!

My solution was to use strips of roofing felt. At around 1mm thickness, I could use it to even out some of the inconsistencies. Eventually, it would be hidden by ballast, so .................

In this photo you can see that the pointwork in the through station has been levelled. Also you will notice I have invested in some plants - a mixture of alpine perennials and a few annuals to provide a bit of colour.

Various other depressions and high spots have been levelled around the garden. Trains are now running a lot more smoothly.

Stream

I also took the opportunity to dredge the sump at the bottom of the stream - you'll notice the dead leaves in the photo above - the water from the sump (which I am sure is rich in nutrients) used to help establish the new plants.

At the same time, the stream was sluiced through to rid it of leaves and rain-washed soil. The resident frog in the sump (I refused to call it a pond) looked on with interest but seemed to enjoy the refreshed water - a combination of rain water from the butt and tap water.

As can be seen, the weekend ended with rain. The wires in the background are those for the terminus station which need to be threaded through to the control panel in the leant-to.

Control panel

This is still very embryonic. A few wires soldered together to check on circuits and to enable me to run test trains. One day, this will become a well crafted control centre ........ In the meantime............... needs must!

<< Go to Progress Report 3

Friday was a gorgeous day - unbroken sunshine and, for almost the first time this year, pleasantly warm. An impromptu barbecue was organised after work. Very pleasant to sit in the garden with a glass of fizz and blackened meat which was once a kebab, with a train chugging away in the background.

Snagging

The weekend was spent mostly in sorting out some of the

snags from tracklaying so far. I decided that, rather than lifting track and levelling the underlying trackbed, I would try a less radical solution. I figured that even after re-laying the blocks, they could re-settle and then I'd have to re-do the whole procedure. Besides, I wanted an easier life!

snags from tracklaying so far. I decided that, rather than lifting track and levelling the underlying trackbed, I would try a less radical solution. I figured that even after re-laying the blocks, they could re-settle and then I'd have to re-do the whole procedure. Besides, I wanted an easier life!My solution was to use strips of roofing felt. At around 1mm thickness, I could use it to even out some of the inconsistencies. Eventually, it would be hidden by ballast, so .................

In this photo you can see that the pointwork in the through station has been levelled. Also you will notice I have invested in some plants - a mixture of alpine perennials and a few annuals to provide a bit of colour.

Various other depressions and high spots have been levelled around the garden. Trains are now running a lot more smoothly.

Stream

I also took the opportunity to dredge the sump at the bottom of the stream - you'll notice the dead leaves in the photo above - the water from the sump (which I am sure is rich in nutrients) used to help establish the new plants.

At the same time, the stream was sluiced through to rid it of leaves and rain-washed soil. The resident frog in the sump (I refused to call it a pond) looked on with interest but seemed to enjoy the refreshed water - a combination of rain water from the butt and tap water.

As can be seen, the weekend ended with rain. The wires in the background are those for the terminus station which need to be threaded through to the control panel in the leant-to.

Control panel

This is still very embryonic. A few wires soldered together to check on circuits and to enable me to run test trains. One day, this will become a well crafted control centre ........ In the meantime............... needs must!

<< Go to Progress Report 3

Wednesday, May 03, 2006

Progress Report 3 - A tour of the line

May Bank Holiday provided me with an opportunity to move much further forward with tracklaying which is now almost complete. The trip to Bay Models in Carnforth to collect 20 x 3m lengths of LGB rail and two sleeper packs was 'interesting'. My wife found the house in which her great grand uncle resided (in Allithwaite) and then we motored down a rain-lashed M6 with around 1.5m of rail in its cardboard tube poking out through the rear window of my Mazda MX5, my wife clutching on to it. Each bump caused an interesting snaking motion which, like a Mexican wave translated itself back down the tube!

Apart from one 3m length, all that rail is now laid.

A tour of the line

Emerging from the tunnel to the storage sidings we enter the main station. The run-round loop is completed (though not yet wired) and the siding to the right it to be laid. The base for the station is two 3'x2' paving slabs which so far have blunted three masonry bits. I will bide my time (and buy more masonry bits) before laying the final siding.

The station throat. All points are laid, but not yet wired up, hence the cables. Those screws need a dab of brown paint!

Through the underbridge which carries the upper line forming the figure of 8. This track is Aristocraft which has black sleepers and paler brass - but is a joy to lay as it is more flexible and resists springing back - but is apt to kink if you are not careful.

Rising up the incline (roughly 1 in 40) .......

...... and around the rocky outcrop........

..... to the cross-over. The line to the right is used to reverse trains if needs-be.

The line now curves to the left into the through station (yet to be named).

To the left is the siding and ahead is the cross-over for the passing-loop. You''ll notice a slight bow in the siding. Frustratingly the blocks have settled and there is a dip right under the pointwork which I now realise will have to be relaid. Past experience with OO gauge modelling has taught me that unless pointwork is perfectly level trouble will ensue!

Through the station - there will eventually be an island platform to the right. We're on LGB track here which is very robust but the 3m lengths can be somewhat unwieldy.

Looking back into the station ........

..... we then cross the long bridge. Incidentally, you'll notice the sun is shining - so it is now about 5 degrees warmer than when the track was laid - and already I am noticing the effects of temperature on rail expansion..............

The further rail is approximately 2mm longer now than when it was laid two days ago! A hacksaw job - and I will have to check all my expansion gaps again!

We now enter the non-scenic section behind the sheds. Interestingly, this seems to be the part which most interests visitors!

Back on to concrete blocks here.

Through the conifers and back out into the garden. This section was meant to be 'hidden', but now the track has been laid I quite like it. I may remodel the approach so the trains can be seen snaking through the trees.

After traversing the cross-over, a gentle climb of 1:70 towards the overbridge crossing the lower line which is now on our right.

This is Tenmille track - which has a slightly narrower profile - more like bullhead than flat-bottom rail. It has been ballasted with 'Alpine pink' gravel held in place with exterior PVA adhesive. The wire to the left will soon be buried. It leads to the furthermost point for the through station.

Looking back across the overbridge which crosses the lower line at the centre of the figure of 8. As the lines cross at an angle I needed a skewed bridge. The LGB girder bridge was sliced in half and skewed. I looks slightly drunken on the left - has yet to be fixed into place and cemented in.

The line now curves to the right. The terminus station is below to the left.

The line now descends (1:40). Ahead is the bridge over the stream which will later be extended into the area on the right. The ballasting here is a mix of gravel:sand:cement in the proportion 2:1:1. Brushed on dry and then watered. Much easier to lay than the PVA method and I must admit I am warming to its appearance. It doesn't look as artificial as the neat gravel and PVA method!

A curve to the right .........

....before curving back to the left in a large circle. The through-station is across the lawn dead ahead at this point.

Across the patio bridge. To the left will be a small patio - eventually. Viewing the line from this level, I am alarmed to see how uneven the track seems to be. Some relaying might be required here otherwise there might be some interesting accidents as trains traverse the bridge!

The line now meanders back towards the terminus station which can be seen ahead. I like this section of the line. I'm hoping that, once the vegetation becomes more established and the stream (to the left) flows through, on a summer's evening I can sit on the patio with a cool beer ......

We rejoin the railway at the terminus station to our right.

A test train has been run and already I have identified several 'snags' which need ironing out - mostly caused by the blocks settling. But there's plenty of time for that.............................

Apart from one 3m length, all that rail is now laid.

A tour of the line

Emerging from the tunnel to the storage sidings we enter the main station. The run-round loop is completed (though not yet wired) and the siding to the right it to be laid. The base for the station is two 3'x2' paving slabs which so far have blunted three masonry bits. I will bide my time (and buy more masonry bits) before laying the final siding.

The station throat. All points are laid, but not yet wired up, hence the cables. Those screws need a dab of brown paint!

Through the underbridge which carries the upper line forming the figure of 8. This track is Aristocraft which has black sleepers and paler brass - but is a joy to lay as it is more flexible and resists springing back - but is apt to kink if you are not careful.

Rising up the incline (roughly 1 in 40) .......

...... and around the rocky outcrop........

..... to the cross-over. The line to the right is used to reverse trains if needs-be.

The line now curves to the left into the through station (yet to be named).

To the left is the siding and ahead is the cross-over for the passing-loop. You''ll notice a slight bow in the siding. Frustratingly the blocks have settled and there is a dip right under the pointwork which I now realise will have to be relaid. Past experience with OO gauge modelling has taught me that unless pointwork is perfectly level trouble will ensue!

Through the station - there will eventually be an island platform to the right. We're on LGB track here which is very robust but the 3m lengths can be somewhat unwieldy.

Looking back into the station ........

..... we then cross the long bridge. Incidentally, you'll notice the sun is shining - so it is now about 5 degrees warmer than when the track was laid - and already I am noticing the effects of temperature on rail expansion..............

The further rail is approximately 2mm longer now than when it was laid two days ago! A hacksaw job - and I will have to check all my expansion gaps again!

We now enter the non-scenic section behind the sheds. Interestingly, this seems to be the part which most interests visitors!

Back on to concrete blocks here.

Through the conifers and back out into the garden. This section was meant to be 'hidden', but now the track has been laid I quite like it. I may remodel the approach so the trains can be seen snaking through the trees.

After traversing the cross-over, a gentle climb of 1:70 towards the overbridge crossing the lower line which is now on our right.

This is Tenmille track - which has a slightly narrower profile - more like bullhead than flat-bottom rail. It has been ballasted with 'Alpine pink' gravel held in place with exterior PVA adhesive. The wire to the left will soon be buried. It leads to the furthermost point for the through station.

Looking back across the overbridge which crosses the lower line at the centre of the figure of 8. As the lines cross at an angle I needed a skewed bridge. The LGB girder bridge was sliced in half and skewed. I looks slightly drunken on the left - has yet to be fixed into place and cemented in.

The line now curves to the right. The terminus station is below to the left.

The line now descends (1:40). Ahead is the bridge over the stream which will later be extended into the area on the right. The ballasting here is a mix of gravel:sand:cement in the proportion 2:1:1. Brushed on dry and then watered. Much easier to lay than the PVA method and I must admit I am warming to its appearance. It doesn't look as artificial as the neat gravel and PVA method!

A curve to the right .........

....before curving back to the left in a large circle. The through-station is across the lawn dead ahead at this point.

Across the patio bridge. To the left will be a small patio - eventually. Viewing the line from this level, I am alarmed to see how uneven the track seems to be. Some relaying might be required here otherwise there might be some interesting accidents as trains traverse the bridge!

The line now meanders back towards the terminus station which can be seen ahead. I like this section of the line. I'm hoping that, once the vegetation becomes more established and the stream (to the left) flows through, on a summer's evening I can sit on the patio with a cool beer ......

We rejoin the railway at the terminus station to our right.

A test train has been run and already I have identified several 'snags' which need ironing out - mostly caused by the blocks settling. But there's plenty of time for that.............................

Subscribe to:

Posts (Atom)

.JPG)