Contents

As indicated in Part 1, I assembled a CTC DIY A8 3D printer from a kit which I picked up on eBay for £80GBP. It has enabled me to explore the potential of 3D printing for my 16mm scale garden railway at reasonable cost and I am pleased with the results I've had so far. It isn't perfect - but considering the printer was substantially cheaper than many alternatives, I think it was well worth the outlay.

Part 1 covered putting the kit together, this part outlines how to get the printer up and running for the first time. As discussed in Part 1, the instructions lack some clarity in essential places so, if you are following in my footsteps, hopefully I can help you take your first steps.

There are several steps which need to be taken before the printer can be used for the first time - some of which do not seem to be covered in the instruction manual.

It is a good idea to preheat the bed and printhead before making adjustments, and it's essential before loading the filament. On the A8, it is quite a simple process.

Turn on the printer and after the LCD has displayed its welcome message the screen presents a summary of the printer's status.

Access the menu by pressing the centre button to the right of the LCD screen

...... and then press the right hand button to select this option.

This displays the Quick Settings menu.

Move the pointer (square) down to "Preheat PLA" and press the right button to select it.

This should then take you back to the main screen, only this time "Preheat PLA" is displayed at the bottom of the screen and you should see the temperature readings rising at the top of the screen .....

This should then take you back to the main screen, only this time "Preheat PLA" is displayed at the bottom of the screen and you should see the temperature readings rising at the top of the screen .....

.... until the actual temperatures of the printhead and the printbed have reached their targets (190 and 55 degrees respectively).

NOTE: At any point you can move back to the previous menu by pressing the left button

Tighten the four spring-loaded screws holding the printbed to the baseplate until the printbed is about 1/4 of the way down each screw.

Slide the printhead carriage (on the X-axis) and the printbed (on the Y-axis) so the printhead is roughly in the centre of the printbed.

NOTE: If the printhead carriage and the printbed won't move, the stepper motors might have been actuated and so they need to be disabled - see Disabling the stepper motors below

Lower the X-axis by twisting the threaded rods on either side of the printed with your fingers/thumbs until the printhead just touches the printbed.

NOTE: If the Z-axis microswitch stops the left had X-axis plastic bracket from being lowered sufficiently, then slacken off the two screws holding the microswitch mounting plate and slide it downwards.

Measure the height of the left hand X-axis bracket above its stepper motor and make a note of the height.

Measure the same height for the right hand bracket and adjust it by twisting the threaded rod until it matches the height of the left hand bracket.

The printbed must be perfectly level to ensure the printhead remains the same distance above it when printing.

Move the printhead close to each corner of the printbed and adjust the spring-loaded corner screws until a piece of ordinary printer paper is just released from beneath it.

NOTE: You may need to go round the the bed doing the adjustments twice as the baseplate has a tendency to distort when the screws are tightened.

The next job is to adjust the Z-axis microswitch so detects when the printhead is at its home position above the printbed.

Loosen the two screws holding the Z-axis microswitch bracket so it can slide up and down.

Slide the bracket up until you can hear the microswitch click as it makes contact with the lower part of the plastic X-axis bracket.

NOTE: I find it easier to tighten the left hand screw first and then swing the bracket up and down slightly to find the exact point when the switch clicks, then tighten up the right hand screw.

NOTE2: It is possible to download and print out Z-axis adjusters from Thingiverse to make this process easier - eg https://www.thingiverse.com/thing:2456067

To move the printhead carriage and printbed manually, the stepper motors need to be disabled.

Access the main menu on the LCD display by pressing the middle button.

Move the pointer down to "Quick settings"

Press the Right button to select it

Move the pointer down to "Disable Stepper"

Select this with the Right button

If you haven't already done so, preheat the printhead for the type of filament you are using (see above)

The first job is to cut the end of the filament at an angle with a pair of scissors or snippers. Then make sure the last 10cm of the filament is perfectly straight. If it is not, it will curl up inside the extruder and miss the entrance to the printhead.

Next, release the tension on the extruder by depressing the lever section on top of the extruder with your thumb - it is a good idea to support the bottom of the extruder with your fingers so the carriage isn't put under too much pressure.

Feed the filament into the hole (beside your thumb). You might need to twist the filament if there is a slight bend in it so it locates the hole into the hot-end of the printhead. You will know when you have been successful because melted filament will appear out of the printhead.

Release the lever so the extruder wheel can grasp the filament.

To check the extruder is feeding the filament properly, access the main menu on the LCD panel by pressing the middle button.

Use the lower button to scroll down to "Extruder"

Select this option with the right button. From the next menu select "Extr. Position" with the right button

Use the UP button to feed the filament through the extruder (Yes, it's counter-intuitive but the Up button feeds the filament downwards and the Down button feeds it upwards).

You should see the filament oozing out of the nozzle when the up button is being pressed. If not, give the filament a bit of assistance by pushing it down into the extruder with your fingers. You might hear a clicking sound if the knurled wheel in the extruder is slipping on the filament.

If it doesn't work, you might need to disassemble the extruder and clean the knurled wheel - it can sometimes get clogged with plastic.

Finally, I feed my filament through the handles of a document clip attached to the top of the printer frame to help ensure it doesn't become snagged.

You can download and print-out various filament guides from Thingiverse if you fancy something a bit more sophisticated.

I have positioned my reel of filament as close to the height of the printer as is possible. At the moment this is on top of a couple of boxes on a shelf - eventually I will create something a bit more elegant!

Now you have finished setting up your printer, we come to the exciting part - printing out your first object.

First, you need to find an object to print out. I would suggest you start with something small scale. This helps you avoid disappointment if it doesn't work out, doesn't stretch the settings on your printer and overtax your setting-up arrangements and also won't keep you waiting too long until it's finished.

As my garden railway is 16mm scale and set in the 1930s, I opted for something which might have been found on a platform during that era - a wicker pigeon basket.

Firstly, I went to the Thingverse.com website and searched for 'Pigeon basket".

I then downloaded the files on to my computer and extracted them.

Once the files had been downloaded, I loaded them into the version of Cura which came on the CD included in the printer kit. When Cura loads, it might indicate that there is a more recent, more powerful version of Cura available but I discovered that the latest version won't run on the antiquated laptop I use in my workshop and so I have remained with this earlier version.

The model of the basket was far too large even for a 16mm scale railway and so .......

,,,,,, I selected the scaling tool (the middle icon in the bottom left of the screen). I worked out that the length of a basket in 16mm scale would be about 30mm .......

....... and so changed the Size Y dimension to 30

I next had to check that the settings were correct for my printer and the filament I was using.

NOTE: If you have the most recent version of Cura, you can select the settings for an Anet A8 printer.

It is important that you set the size of filament to 1.75 and the nozzle size to 0.4 (at the base of the basic settings)

You might need to experiment with the settings for the printhead temperature and printing speed to get the best out of the combination for your printer and the type of filament you are using but for now, try using the settings shown above.

NOTE: To help ensure the first layer sticks to the printbed, I would suggest using a Brim support.

Once you have done this, the software will tell you how long the print will take and how much filament it will use. Don't worry if your figures are slightly different to mine, I have been tweaking some of the settings in the background since I got the printer.

You now need to generate the slicing code used by the printer. From the file menu, select "Save GCode".

Save the file somewhere you will be able to relocate it and then save it or copy it on to a Micro SD card.

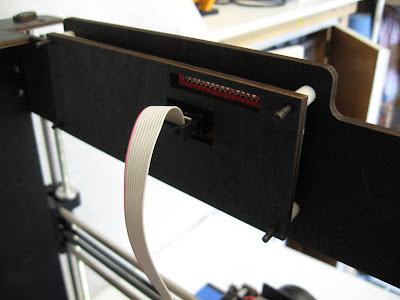

Once saved and ejected from the computer, the SD card needs to be inserted into the card slot on top of the motherboard on the printer.

Access the main menu on the LCD screen and select "SD Card" from it (with the right button)

Then select "Mount Card"

Next, select "Print file"

You may only have one file on the card initially, but if not scroll down until you find the gcode file you saved on it (in my case PigeonBasketAllClosed).

The display should now revert to the home screen, with "Printing" showing up at the base of it.

It might take a short while for the printer to start as the bed and printhead temperatures need to be adjusted to those required by the gcode for your object.

Once the printing has started, you will be able to watch in awe and wonder as it gradually takes shape on the printbed.

You can check the progress of the printing by seeing how much, in percentage terms, of the model has been printed so far.

If something goes wrong, you can abort the printing by either pressing the reset button in the middle of the motherboard or, less dramatically, by selecting "Stop Print" from the SD Card menu.

This may all sound daunting at first but you'll be astonished at how quickly all this becomes second nature to you.

Don't despair if, or rather when, things go wrong. With such a complex process, it's inevitable that something will go wrong at some point. I am rapidly collecting a box full of misprinted or part-printed parts. Rather than seeing them as failures I am trying to see them as learning experiences.

I suppose my most ambitious print so far has been two 3D printed diesel locomotives which I have coupled back to back as per Australian sugar cane railways. (See How I 3D printed a pair of diesel locos - pending)

I still have many ideas for the printer. All I need is time to implement them - but life keeps getting in the way!

There is plenty of information on the internet about how to get the best out of your printer. I've lost count of the number of forum posts I've read, web pages I've browsed through and YouTube videos I've watched on various aspects of the 3D printing.

I'm now on my third reel of filament and have made quite a few changes to the printer which came out of the box a few months ago. When I first floated the idea of investing in what must be the cheapest commercially available 3D printer with some fellow modellers on one of my forums, one responded, "Don't think of it as buying a printer, think of it as taking on a project". He wasn't far wrong.

Good luck and happy printing!

If you want to see what modifications I have made to my printer so far, see Part 3 - Modifying my budget 3D Printer - pending