Having acquired a Bachmann Lynton & Barnstaple Lyn loco for a reasonable price and converted her to battery RC (see How I converted Bachmann Lyn to battery RC), I was concerned that there were a few problems with the way she ran on my railway. Firstly, the overhang at each end was so great that the out-swing on my tight curves caused problems with the couplings. Secondly, the scale was wrong. The Bachmann loco is constructed to a somewhat unusual scale of 13.8mm to the foot, which makes her slightly under-scale for my 15mm / ft railway. Presumably, this is a compromise between the 1' 11.5" gauge of the L&B track and the 45mm gauge of the model.

Having acquired a Bachmann Lynton & Barnstaple Lyn loco for a reasonable price and converted her to battery RC (see How I converted Bachmann Lyn to battery RC), I was concerned that there were a few problems with the way she ran on my railway. Firstly, the overhang at each end was so great that the out-swing on my tight curves caused problems with the couplings. Secondly, the scale was wrong. The Bachmann loco is constructed to a somewhat unusual scale of 13.8mm to the foot, which makes her slightly under-scale for my 15mm / ft railway. Presumably, this is a compromise between the 1' 11.5" gauge of the L&B track and the 45mm gauge of the model.So, should I live with the anomalies, modify the body or find a more appropriate model which could be mounted on the motor block? In the end, I decided on a compromise. I found a very attractive 3' narrow gauge 4-4-0T loco which ran on the Schull & Skibbereen Railway in Ireland.

|

| Source: https://durrushistory.files.wordpress.com/2014/08/07-img_4667.jpg |

However, the S&S loco had inside frames whereas the Lyn has outside frames with fly cranks. I then discovered a Cork & Muskerry 0-4-4T loco with outside frames but I didn't like the body as much as the S&S loco, so I decided to merge one with the other.

The 7mm narrow gauge modellers' association have produced a beautifully detailed scale drawing of the S&S loco but, as far as I know, there is no drawing of the C&M loco. I therefore had to study the few photos which exist of the C&M loco to marry the Bachmann chassis with to the actual 0-4-4T chassis. Quite a few compromises were made as the wheelbase and driver diameters are not equivalent, but I have never let such details previously interfere with my model making. Undaunted, I pressed on by superimposing the motor block dimensions on the drawing.

The body needed to be lowered, the front of the running plate needed to be shortened and the rear bogie needed to be compressed slightly, but I felt it was feasible.

Unlike my previous scratchbuilds, I decided to construct this loco entirely from 3D printed parts which I firstly needed to draw with a 3D drawing package. I opted for TinkerCAD, an online 3D drawing app which is designed for kids to use so it has a very gentle learning curve. However, despite its fairly limited tools, it is capable of producing quite detailed objects.

As the build was going to be quite ambitious, compared with my previous efforts (eg see How I drew a Southwold Railway open wagon with TinkerCAD), I decided to combine each of the parts into an overall drawing of the loco, partly to check they would fit together and partly so I could see what the loco looked like.

After drawing all the principal parts of the loco and printing them out, ......

...... I started on the construction.

The rear of the cab was glued to the footplate .......

...... followed by the cab and tank sides.

The front of the cab with the rear of the boiler was then attached.

The smokebox was attached to the front of the boiler, .....

..... and the two halves of the boiler were united.

The tops of the tanks were then glued into place, together with the fronts of the tanks

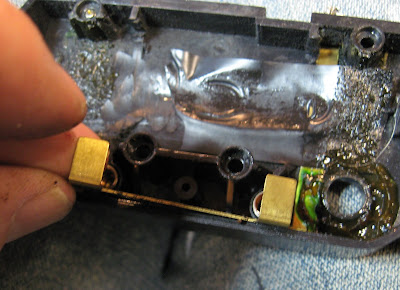

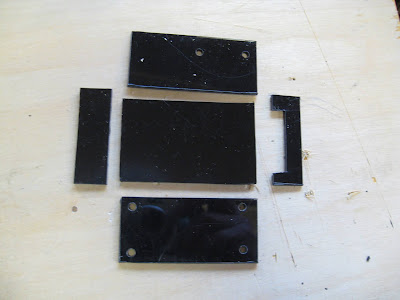

At this point, I realised that I needed to fit backs to the tanks so these were cut from 2mm thick plasticard. The backs of the tanks were later reproduced as TinkerCAD drawings.

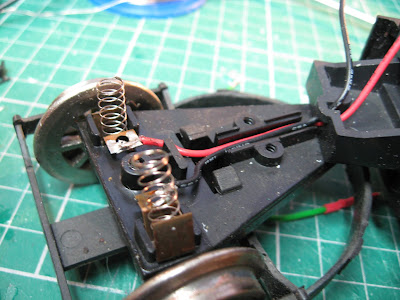

I then tackled the four wheel trailing bogie. I decided to use the two two-wheel bogies from the Bachmann Lyn as these included neatly engineered sprung suspension. The two bogies were shortened.....

.... and extraneous mouldings removed.

They were then joined with a short piece of aluminium plate with self-tapping screws,.......

...... and the outside frames glued into place .....

....using a bracket printed in TinkerCAD.

A bracket for my own style of hook and loop couplings was then screwed on the the base of the bogie....

..... and everything given a couple of coats of Halfords grey primer from an aerosol rattle can, followed by a brush-painted coat of back acrylic.

The dome, chimney and safety valve were then glued on to the top of the boiler and the toolboxes(?) were then glued either side. The motor block was test-fitted as was the bogie to make sure I had got the dimensions correct.

I realised that there now needed to be some infill beneath the running plate and so, after mocking something up from oddments of plasticard, I then reproduced the two sub-chassis pieces in TinkerCAD. One for the front ......

.... and one for the rear.

The rear part was glued beneath the footplate ......

A self-tapping screw holds the rear of the motor block to the bracket ......

.... and the bogie was connected to the rear of the motor block using one of the original pivot screws and pivot hole.

The front part was left floating so that it could be screwed into place with a single screw to serve a triple purpose: infilling beneath the running plate, retaining the cylinders and also acting as a bracket to hold the front end of the motor block. A mounting block for my hook and loop couplings was then glued on.

At this point, I realised that the body was sitting slightly too high on the motor block and so, by whittling away at the running plate, the toolboxes and the boiler, I was able to to lower it by around 5mm. I now felt the loco was looking more realistic.

The firebox was glued into the cab and I glued the steps to the footplate. However, these later needed to be removed as the bogie swings out too much when taking my tight curves.

The loco then went into the paintshop and given a couple of coats of Halfords grey primer from a rattle can aerosol. This was allowed to harden off overnight before the various cracks and cavities were filled with Squadron White Putty. The body was then rubbed down with 80 grit followed by 240 grit emery papers. Another coat of primer was then followed by four light coats of Halfords Rover Brooklands Green body spray.

Handrail knobs from Garden Railway Specialists were then glued into holes drilled in the boiler and smokebox and brass rod passed through and shaped into handrails.

The interior of the cab was painted with cream coloured acrylics and the pipes, regulator and knobs on the backhead were painted copper, gold and red.

Electrics

My standard battery/RC circuit was used for this loco - three solder-tagged 18650 li-ion cells (from Ecolux) were wired up to a 3S battery protection board and a four-way JST balance charge socket. This was in turn wired through a Single-Pole Double-Throw (SPDT) toggle switch to a DC power socket and to a Deltang Rx65c receiver/controller and a MyLocoSound Universal Steam Soundcard.

She has so far had a couple of test runs and required a small amount of modification to ease the motion, but looks as if she will make an interesting and slightly different addition to the fleet.

[Awaiting video of first run]